Organic Apple Juice Concentrate Making Machine

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JPF-APM009

- Type:

-

apple juice making machine

- Voltage:

-

380V/50HZ

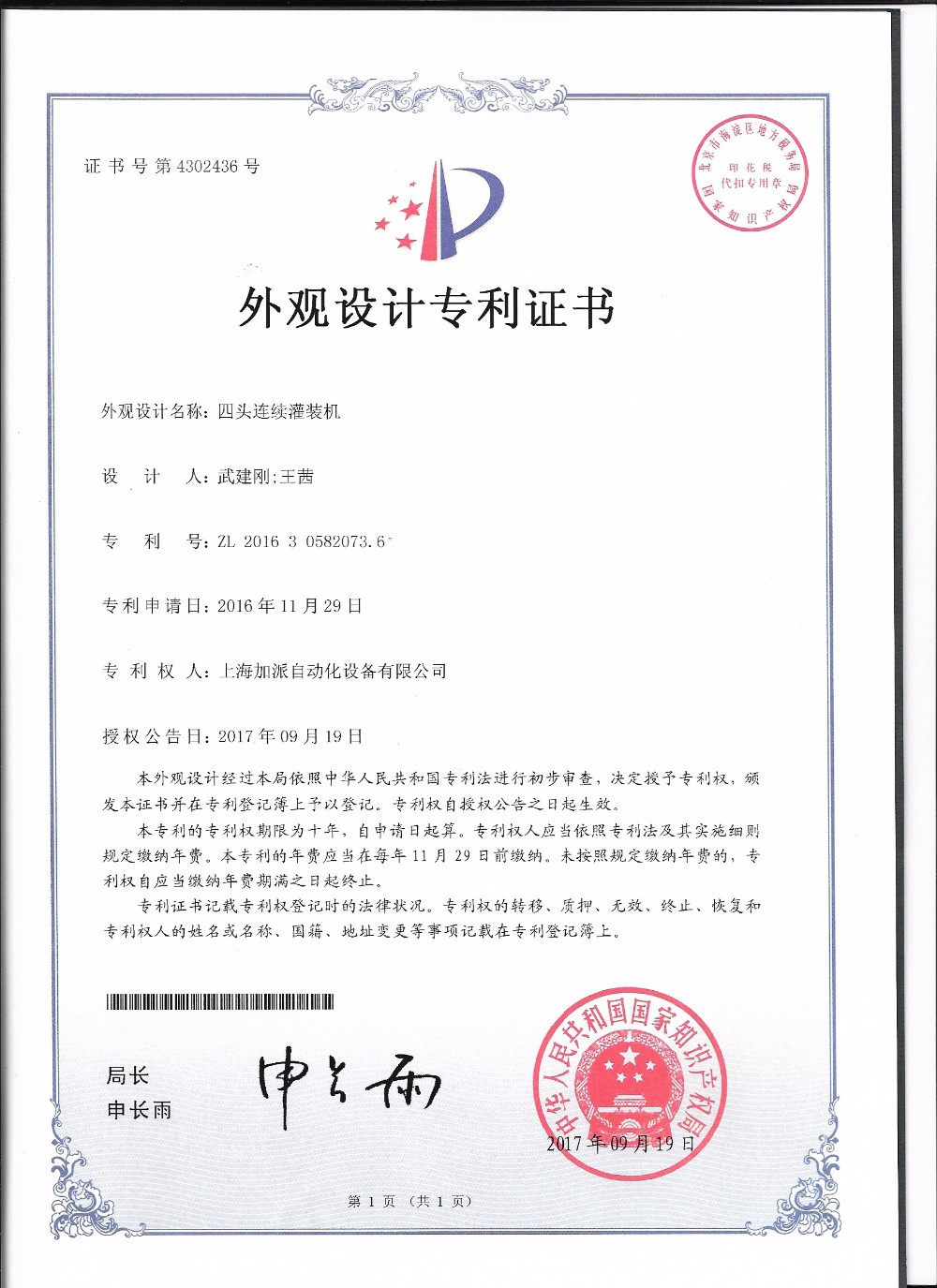

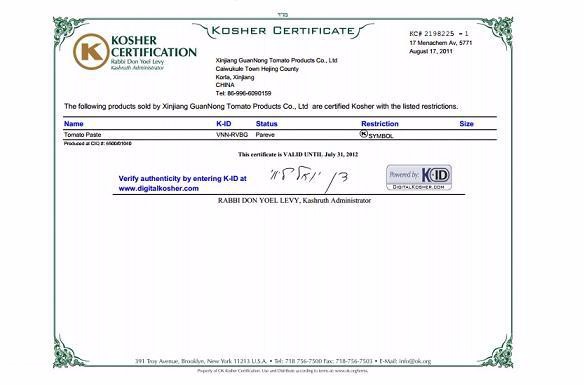

- Certification:

-

CE/ISO9001

- Warranty:

-

12months, 12 months

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

apple juice making machine

- Name:

-

complete apple juice production line

- Application:

-

fruit juice factory

- Item:

-

apple juice making machine

- Material:

-

Food Grade Stainless Steel

- Feature:

-

Easy Operation

- Usage:

-

apple juice extracting machine

- Function:

-

Multifunctional

- Supply Ability:

- 10 Set/Sets per Week apple juice making machine

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion.Fumigation-free package helps the smooth customs clearance.The big size machine will be fixed in container without package.

- Port

- Shanghai port

- Lead Time :

- 60 days after orderconfirmed

APPLE JUICE MAKING MACHINE

China is the world’s largest producer of apple and the main pear producer, Apple pear juice is divided into clear juice, turbid juice nfc concentrated juice and so on. Apple Pear processing plant equipment is including cleaning, crushing, juice, enzymatic hydrolysis, membrane filtration, enrichment, sterilization, aseptic filling and other equipment.Shanghai JUMP automatic equipments Co., Ltd. Development and production of apple pear processing equipment, such as crushing, juicer equipment has a simple structure, easy to operate, high production efficiency, at home and abroad at the leading technical level.

Technical Data For Orange / apple/ pear processing line

complete apple juice production line:

China is the world’s largest producer of apple and the main pear producer, Apple pear juice is divided into clear juice, turbid juice nfc concentrated juice and so on. Apple Pear processing plant equipment is including cleaning, crushing, juice, enzymatic hydrolysis, membrane filtration, enrichment, sterilization, aseptic filling and other equipment.Shanghai JUMP automatic equipments Co., Ltd. Development and production of apple pear processing equipment, such as crushing, juicer equipment has a simple structure, easy to operate, high production efficiency, at home and abroad at the leading technical level.

Product Advantages:

*The processing volume from 3 tons the day to 1500 tons per day

* Use high efficiency belt juicer to improve juice efficiency and juice yield.

* Production process fully automatic PLC control, reduce labor intensity, improve production efficiency

* Aseptic tube sterilizer and aseptic filling machine, isolate the contamination of bacteria, ensure food safety, prolong the shelf life of products.

Whatsapp/Line/Wechat/Mobile: 008613681836263 Welcome any inquiry!

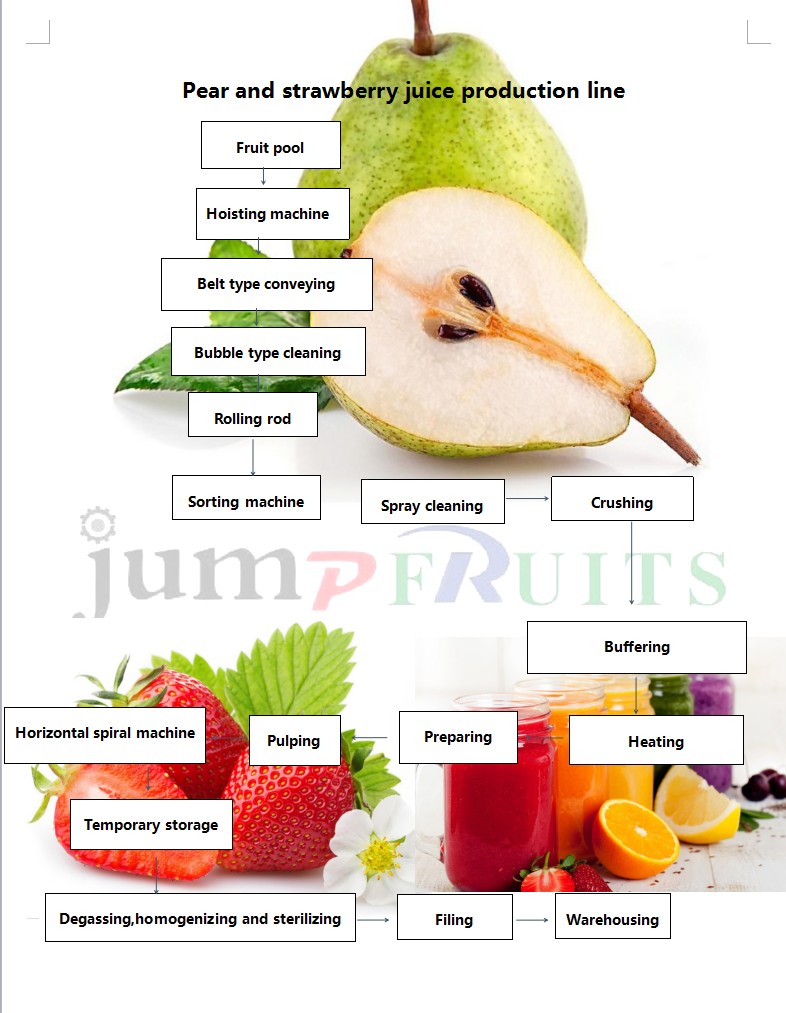

Flow of processing line:

The final Package of apple juice :

glass bottle, PET plastic bottle, cans, aseptic soft package, roof pack 2L-220L sterile bag, carton package, plastic bag, 70-4500g tin can.

Select stainless steel bracket, food-grade and hard plastic or stainless steel scraper, smoothing blade architecture to prevent the fruit jam; Using imported anti-corrosion bearings, double-sided seal; with continuously variable transmission motor, variable frequency Speed and low operating costsTitle goes here.

Stainless steel roller conveyor, rotation and solution, a full range of check, no need ends. Manmade fruit platform, painted carbon steel bracket,stainless steel antiskid pedal,stainless steel fence.

C. Apple juicer machine

Fusing Italian technology, multiple sets of cross-blade structure, crusher size can be adjusted according to customer or specific project requirements, it will increase the juice juice rate of 2-3% relative to the traditional structure , which is suitable for production of onion sauce, carrot sauce, pepper sauce , apple sauce and other fruits and vegetables sauce and products

D. Apple juice Evaporator

Single-effect, double-effect,triple-effect and multi-effect evaporator, which will save more energy; Under vacuum, continuous low temperature cycle heating to maximize the protection of nutrients in the material as well as the originals. There are steam recovery system and double times condensate system, it can reduce the consumption of steam;

E. apple juice Sterilization machine

Having obtained nine ed technology, take full advantages of the material’s own heat exchange to save energy– about 40%