Supply new tomato paste production line in good price

- Machinery Capacity:

-

20000BPH

- Packaging Material:

-

wood

- Filling Material:

-

Powder

- Type:

-

Filling Machine

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location:

-

None

- Showroom Location:

-

None

- Condition:

-

New

- Application:

-

Beverage, Food, Machinery & Hardware, MEDICAL

- Packaging Type:

-

CANS

- Automatic Grade:

-

Automatic

- Driven Type:

-

Electric

- Voltage:

-

220V/380V

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

OEM/JUMP

- Dimension(L*W*H):

-

depend on capacity

- Weight:

-

3500KG

- Certification:

-

CE ISO

- After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Engineers available to service machinery overseas

- Warranty:

-

5 years, 2 Years

- Key Selling Points:

-

Easy to Operate

- Marketing Type:

-

New Product 2020

- Machinery Test Report:

-

Provided

- Video outgoing-inspection:

-

Provided

- Warranty of core components:

-

5 years

- Core Components:

-

Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- Product name:

-

w tomato paste production line in good price

- Material:

-

Stainless Steel 304

- Name:

-

tomato ketchup production line

- Function:

-

production line

- Processing Types:

-

tomato ketchup production

- Usage:

-

tomato paste

- Filling material:

-

pste

- Capacity:

-

1T-50Tper hour

- 10 Set/Sets per Month

- Port

- Shanghai

Product Description

Product Advantages:

1. High production speed achieved by a newly designed head system (single head or twin heads available), improved reliability from a fully PLC controlled self diagnostic operational mode.

2. Greater versatility by meeting various packing standards with different products.

3 Coordinates well with the tube in tube sterilizer, if some malfunction with the filler, the product will be automatic flow back into the buffer tank before the UHT sterilizer.

4. The use of a hermetically sealed empty bag ensures the bag will remain sterile before it is filled.

5. High pressure saturated steam is used for sterilization of the fitment, cap and exposed portion of the filler prior to each filling cycle. NO CHEMICALS are required.

6. The sealing of the fill valve on the interior of the fitment keeps product completely away from the package sealing area.

7. The hermetic heat sealing of the fitment provides a tamper evident closure and a superior oxygen barrier.

8. The overall aseptic design of the filler allows uninterrupted. Operation throughout a complete tomato/fruit season, maximizing your plant’s efficiency

9. CIP and SIP available together with tube in tube sterilizer

Main Features

The Aseptic Filling Systems offer a highly effective and reliable aseptic method of bulk packaging for high and low-acid food products, including tomato paste, vegetables and fruit juices, purees, particulates, concentrates, sauces, soups and dairy products. The Aseptic Filler receives drums or bins through roller conveyors. The containers can be drums in a single line, drums on a pallet (4 drums) and bins. The operator places the presterilized bag in the container then they are automatically transported under the filling station. The presterilized bag is manually placed under the aseptic chamber in a sterile environment saturated by overpressure steam. The operator pushes the start cycle and automatically the cap is removed, the bag filled with sterilized product and then recapped. The standard measure system is with load cells but also the volume system is available. At the end of the filling cycle, the roller conveyor transports the containers to the exit.

Detailed Images

Shanghai Jump automatic equipment Co., Ltd. Is modern high-tech joint-stock enterprises, formerly known as Shanghai Qianwei machinery plant, professional engaged in whole plant equipment design, manufacturing, R & D and turnkey project for juice and jam, tropical fruit processing, heat canned fruit juice drinks, tea drinks, yogurt, cheese and liquid milk dairy processing . The employee quality of the company is excellent, the backbone of the engineer and the core technology R & D personnel directly from the original Qianwei machinery factory, also has a number of food engineering and packaging machinery professional master and doctoral, fully equipped with the whole line project design and development, production and manufacture, installation and commissioning, technical training and after-sales service, etc. the comprehensive ability.

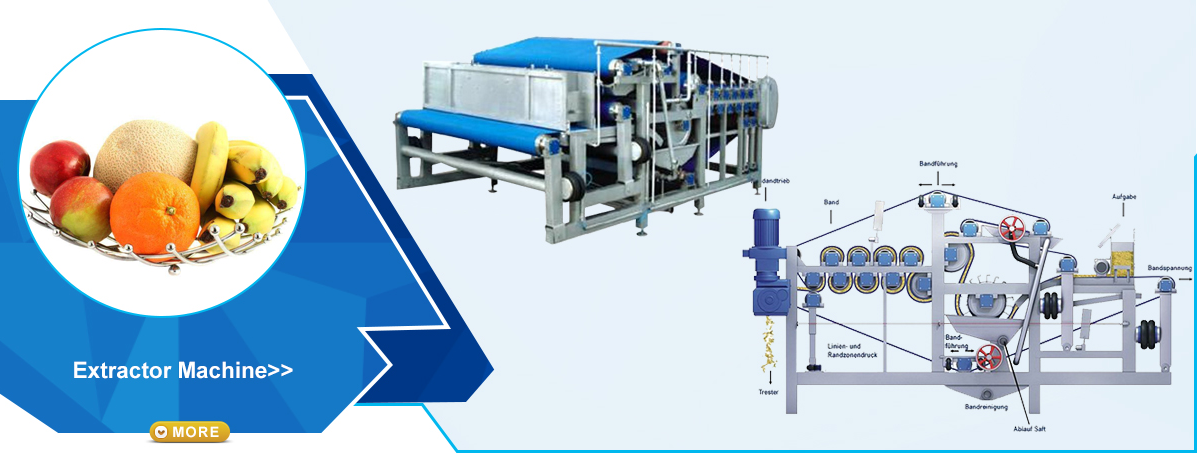

Our main production line

1Tomato paste / puree / jam / concentrate, ketchup, chilli sauce , other fruit & vegetables sauce / jam processing line

2Fruit & vegetables ( orange , guava, cirtrus, grape, pinapple, cherry, mango, apricot.etc. ) juice and pulp processing line

3Pure, mineral water, Mixed beverage, drink (soda, Cola, Sprite, carbonated beverage, no gas fruit drink, herbal blend drink, beer,cider, fruit wine .etc. ) production line

4Canned fruit & vegetables ( tomato, cherry, beans, mushuroom, yellow peach, olives, cucumber, pineapple, mango, chili, pickles and so on. ) production line

5Dried fruit & vegetables ( dried mango, apricot, pineapple, raisin, blueberry .etc. ) production line

6Dairy (UHT milk, pasteurized milk, cheese, butter, yogurt, milk powder, margarine, ice cream)production line

7Fruit and vegetable powder (Tomato, pumpkin, cassava powder, strawberry powder, blueberry powder, bean powder, etc. ) production line

8Leisure snack (Dried freeze-dried fruit, puffed food, french fried potato chips, etc. ) production line

Pre-sales service

We can suggest customer the most suitable machine according to their formula and Raw material. “Design and development”, “manufacturing”, “installation and commissioning”, “technical training” and “after sales service”. We can introduce you supplier of raw material, bottles, labels etc. Welcome you to our production workshop to learn how our engineer produce. We could customize machines according to your real need, and we could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

After-sale service

1.Installation and commissioning: We will send experienced

Products categories

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu