Small scale skim milk powder making machine

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JP-MC5016

- Type:

-

complete plan for dairy production line

- Voltage:

-

220V/380V

- Power:

-

7.5kw

- Weight:

-

600kg

- Dimension(L*W*H):

-

2100*1460*1590mm

- Certification:

-

CE/ISO9001

- Warranty:

-

1 Year warranty,life-long aftersell service

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

skim milk powder making machine

- Application:

-

Glucose, Starch Sugar, Oligose, Maltose, Sorbierit

- Feature:

-

turn key solution,life-long after-sale service

- Material:

-

SUS304 Stainless Steel

- Function:

-

evaporator, filling

- Usage:

-

Industrial Usage

- Name:

-

small scale milk processing machine

- Capacity:

-

500-50000kg/h

- Item:

-

machine for making milk powder

- Color:

-

Silver Grey

- 20 Set/Sets per Month skim milk powder making machine

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion.Fumigation-free package helps the smooth customs clearance.The big size machine will be fixed in container without package.

- Port

- shanghai port

- Lead Time :

- 2-3 months

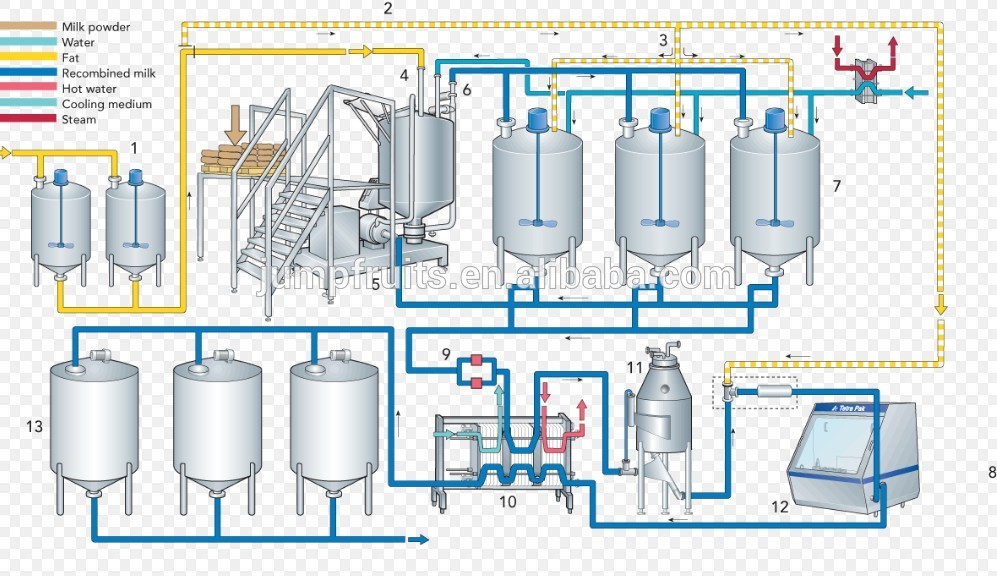

Milk powder process flow:

In the batching process, milk powder production process, in addition to a few varieties (such as whole milk powder, skim milk powder), must go through the ingredients process, the proportion of ingredients according to product requirements. The equipment used in the dosing consists mainly of batching cylinders, powder mixers and heaters. According to the requirements of the formula, the required added microorganisms, trace elements, and various accessories are added as an ingredient.

3.Homogeneous

Homogenization means that the fat and protein in all the ingredients and raw milk are homogenized and dispersed in the product very evenly. The production of full-fat milk powder, whole fat sweet milk powder and skimmed milk powder is not usually done through homogenization, but if the milk powder is added with diced vegetable oil or other difficult-to-mix materials, homogenization is required. The pressure at the time of homogenization is generally controlled at 14 to 21 MPa, and the temperature is preferably controlled at 60°C. After homogenization, the fat globules become smaller, which can effectively prevent the fat from floating and can be easily digested and absorbed.

4.Sterilization

Milk is commonly used in sterilization methods. For specific applications, different products can be selected according to their characteristics. Recently, the most common method is the use of high-temperature short-time sterilization method, because the loss of nutrients in milk is less, and the physical and chemical properties of milk powder are better.

5.Vacuum concentration

The milk is sterilized and immediately pumped into a vacuum evaporator for decompression (vacuum) concentration to remove most of the milk’s moisture (65%) and then enter the dry tower for spray drying to facilitate product quality and reduce costs. It is generally required that the raw milk be concentrated to 1⁄4 of the original volume, and milk dry matter should be about 45%. The condensed milk temperature is 47-50°C. The concentration of different products is as follows:

Whole milk powder concentration: 11.5 to 13 Baume; corresponding milk solid content; 38% to 42%. Skim milk powder Concentration: 20 to 22 Baume degrees; corresponding milk solids content: 35% to 40%.

A fat sweet milk powder concentration: 15 ~ 20 Baume degrees, the corresponding milk solids content: 45% ~ 50%, the production of large-granule milk powder concentrated milk concentration increased.

6.Spray drying

The concentrated milk still contains more water and must be spray-dried to obtain the milk powder.

7.cool down

In plants that are not equipped with secondary drying, cooling is required to prevent separation of fats, and then it can be packaged after sieving (20 to 30 mesh). In the secondary drying equipment, the milk powder is cooled to below 40°C after it is dried twice.

Company Introduction:

Shanghai JUMP GROUP Co., Ltd, is keeping leadership position in the tomato paste and concentrated juice processing line. We also have made brilliant achievements in other fruit& vegetable beverage equipments, such as:

1. Juice production line for orange juice, grape juice, jujube juice, coconut drink/coconut milk, pomegranate juice, watermelon juice, cranberry juice, peach juice, cantaloupe juice, papaya juice, sea buckthorn juice, orange juice, strawberry juice, mulberry juice, pineapple juice, kiwi juice, wolfberry juice, mango juice, sea buckthorn juice, exotic fruit juice, carrot juice, corn juice, guava juice, cranberry juice, blueberry juice, RRTJ, loquat juice and other juice drinks dilution filling production line

2. Can food production line for canned Peach, canned mushrooms, canned chili sauce, paste, canned arbutus, canned oranges, apples, canned pears, canned pineapple, canned green beans, canned bamboo shoots, canned cucumbers, canned carrots, canned tomato paste, canned cherries, canned cherry

3. Sauce production line for mango sauce, strawberry sauce, cranberry sauce, canned hawthorn sauce etc.

We grasped proficient technology and advanced biological enzyme technology, successfully applied in more than 120 domestic and foreign jam &juice production lines and we has helped client gain excellent products and good economic benefits.

Pressure requirements:

1. Must have nearby pasture resources to ensure that fresh liquid milk sources can be supplied in a timely manner.

2. The milk must be processed in a liquid state in time.

3. Must have a complete set of equipment such as a spray drying tower.

Advantage:

1. Milk powder is fresh – from milk to processed milk powder is generally not more than 24 hours.

2. Nutritional balance of milk powder – all nutrients are first dissolved in the milk, once after the spray drying, there is no non-uniform risk.

3. Milk powder reduces secondary pollution — Once into powder, there is no secondary opening and mixing process.

Wet process can better ensure the freshness and nutritional value of the final product, and not all dairy companies can do it with “wet” production. This is mainly determined by the distance between the dairy source and the production plant. Wet process: It is made by directly adding fresh milk to dry ingredients and adding nutrients. There are no intermediate links such as secondary opening and mixing of milk powder, and multiple filtration processes are used to eliminate potential safety hazards and fully guarantee the nutrition. balanced.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.