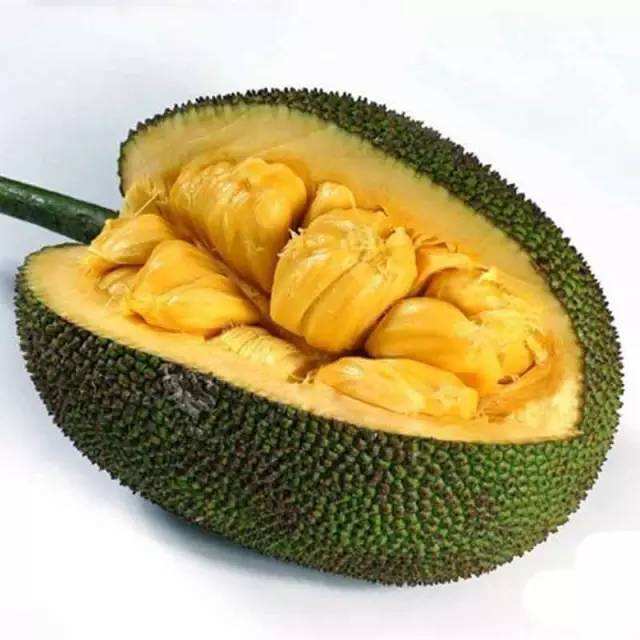

Natural Freeze Dried Jackfruit Processing Machine

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Video technical support

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

1 Year

- Core Components:

-

Motor

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Voltage:

-

220V/380V

- Power:

-

4kw

- Weight:

-

500kg

- Dimension(L*W*H):

-

1560*450*1340mm

- Certification:

-

CE ISO

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Type:

-

Dryer

- Material:

-

Food Grade Stainless Steel

- Function:

-

Washing, peeling , cutting Drying Food

- Application:

-

Pineapple,banana, mango, strawberry

- Capacity:

-

100-500kg/n

- Item:

-

No-pollution Food Dryer Machine

- Supply Ability:

- 5 Set/Sets per Month jackfruit processing machine

- Packaging Details

- Wooden case in 40GP

- Port

- Shanghai

Jackfruit vacuum freeze dryer

Main features of food type freeze dryer:

● Pre-freezing and drying the split structure at the same time, improving the freeze-drying efficiency and shortening the freeze-drying time.

● Space-grade aluminum alloy separator material, double-sided radiant heating, emissivity of more than 90%, good temperature uniformity.

● High-efficiency mixed refrigerant medium, low freezing point and high boiling point, high heat exchange efficiency and long service life.

● Drying curve optimization control algorithm, which can control the heating rate and vacuum value of the product during the drying stage.

● The ed gas guiding design and control technology has strong water-capacity and high drying efficiency.

● The pallet is stamped and formed by aviation anti-rust aluminum alloy, and has a high heat absorption rate through special surface treatment. Each drying compartment is equipped with 2 holding trays.

● Industrial-grade embedded touch screen + dedicated SH-HPSC-III modular controller, the system is stable and reliable, and the control precision is high.

● The professionally designed FD-MANAGER control system can save multiple sets of process recipes, and can adjust the process in real time during the drying process to improve the process optimization rate.

● Flexible manual + automatic control mode, manually used for groping process, automatically used for batch production.

● Accurate sensor calibration to ensure the accuracy of long-term use of process parameters.

● User level and password can be set, and operation management can be decentralized.

● Optional powerful LYO-MEGA PC control system can record and save operating data, curves and alarm records for up to ten years, improve product traceability; at the same time facilitate observation, operation and fault diagnosis.

● Can be customized according to user needs.

|

Style NO.

|

LG-20

|

LG-50

|

LG-100

|

||

|

Shelf area (㎡)

|

20.6

|

52.92

|

105.84

|

||

|

Shelf quantity (layer)

|

8+1

|

9+1

|

18-1

|

||

|

Shelf size (mm)

|

1200*2150*15

|

4900*1200*15

|

4900*1200*15

|

||

|

Shelf spacing (mm)

|

80

|

80

|

80

|

||

|

Number of vehicles (set)

|

2

|

3

|

3

|

||

|

Shelf temperature range (℃)

|

-120

|

||||

|

Maximum freezing capacity (kg)

|

400

|

1000

|

2000

|

||

|

Condensing temperature(℃)

|

-50

|

||||

|

Cooling mode

|

water cooling

|

||||

|

Defrosting mode

|

Spray immersion

|

||||

|

ultimate vacuum (Pa)

|

10

|

||||

|

Power (kw)

|

96

|

150

|

230

|

||

|

Cooling water (m³/h)

|

40

|

80

|

160

|

||

|

Air compression (m³/min)

|

30

|

||||

|

Dimension(m) L*W*H

|

Drying bin:3.7*2.2*2.5

Freezer:3.3*2.0*2.7

Unit: 3.7*2.0*2.2

|

Drying bin:6.8*2.2*2.5

Freezer:6.5*2.0*2.7

Unit: 6.8*2.0*2.2

|

Drying bin:7*2.2*2.5

Freezer:6.5*2.0*2.7

Unit: 3*2.0*2.2

|

||

|

Weight(T)

|

10

|

29

|

46

|

||

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Tomato paste production line

100% Response Rate

canned food processing machine

100% Response Rate

uht milk processing line

100% Response Rate