Multifunctional Concrete Block Machine For Cement Non-fired Brick Production Line

Factory Direct Sales Customizable Automatic Multifunctional Concrete Block Machine

For Cement Non-fired Brick Production Line

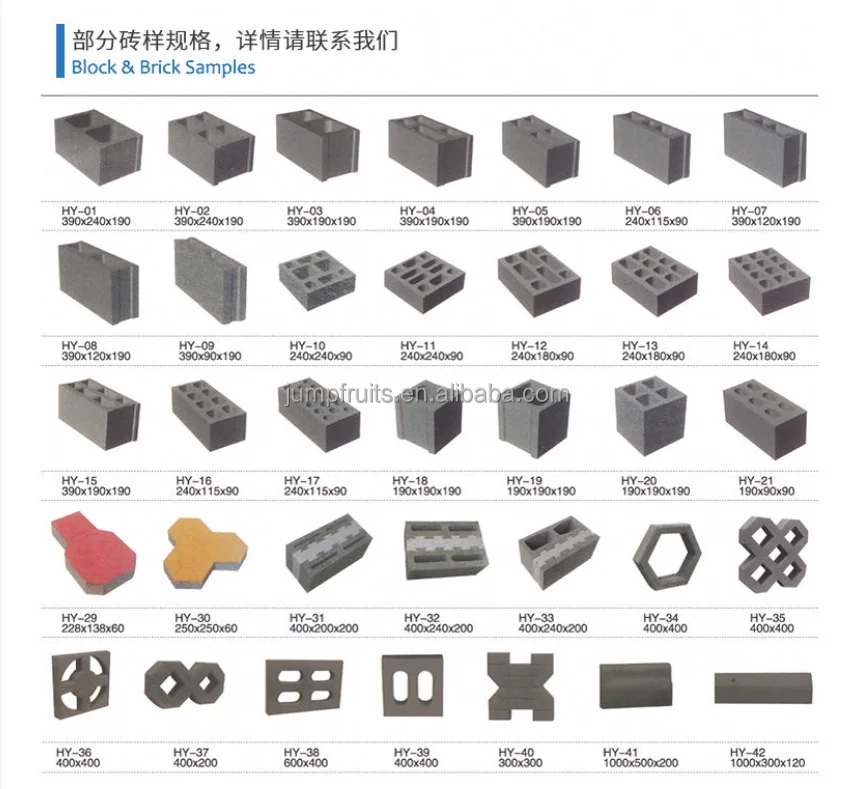

The hydraulic automatic cement brick machine produces raw materials using slag, slag, fly ash, stone powder, sand, stones, cement, etc. as raw materials, scientifically proportioning, adding water and stirring, and pressing cement bricks, hollow blocks or Mechanical equipment for colorful pavement tiles.

3-15 brick machine is also called road tile machine, color brick machine, curb stone machine, non-burning brick machine, brick making machine, hollow brick machine and so on. It does not need to be sintered and can be shipped from the factory through a short time of drying. Low investment and quick results are a popular industry for many investors.

Custom processing: Yes

Molding cycle: 13 seconds

Transmission mode: hydraulic

Exciting frequency: 5100 times/min

Maximum pressure: 22KN

Whole machine weight: 4.8t

Vibration frequency: 5100hz

Working pressure: 8Mpa

Dimensions: 4000*3500*2300cm

Installed capacity: 16kw

Forming pressure: 4 tons

Main vibration form: motor

Total power: 16w

Alias: Block machine, concrete brick, brick machine equipment, hollow brick machine

Purpose: Processing and production of non-burning bricks, hollow bricks, block bricks

Several ingredient methods:

1. Cement + fine sand (fly ash) + medium sand + rice stone (1:1:1:1)

2. Cement + stone powder (1:3)

3. When adding water, it should be based on the dryness and wetness of the raw materials, and it is appropriate to grab it into a dough by hand