mango pulp extraction machine fruit juice production machinery mango jam processing line

- Applicable Industries:

-

Manufacturing Plant, Food & Beverage Factory

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JPF-OI9807

- Type:

-

mango processing line

- Voltage:

-

380V

- Power:

-

4kw

- Weight:

-

100T

- Dimension(L*W*H):

-

1720*1160*1280mm

- Certification:

-

CE ISO

- Year:

-

2019

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Field installation, commissioning and training, Engineers available to service machinery overseas

- Product name:

-

mango pulp extraction machine fruit juice production machinery

- Function:

-

whole mango processing line

- Production capacity:

-

0.5-500T/H

- Material:

-

SUS304

- Advantage:

-

life-long after-sales Service

- Color:

-

Customers' Requirements

- Usage:

-

processing and distribution mango pulp

- Raw material:

-

fresh ripe mangos

- Item:

-

Automatic Fruits Juicer Machine

- 10 Set/Sets per Month

- Packaging Details

- Standard export package.If customer have specail requirement,we will do as customer require

- Port

- Shanghai Port

- Lead Time :

-

Quantity(Sets) 1 – 1 >1 Est. Time(days) 65 To be negotiated

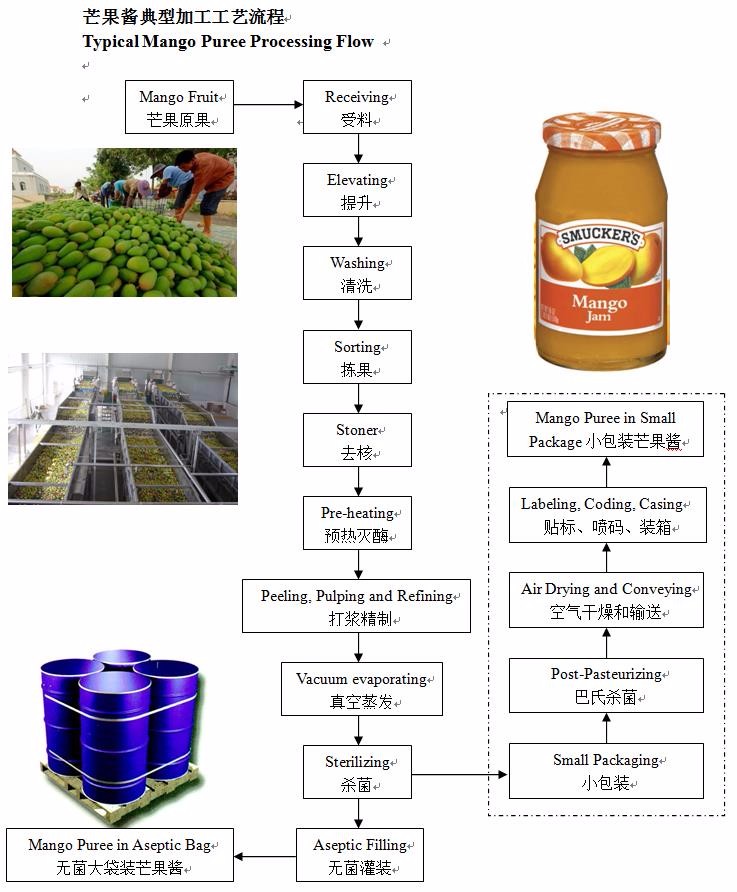

Mango juice processing plant/mango puree production line

Product Application

Applicable to the processing of mango, pineapple, papaya and other tropical fruits, can produce clear juice, cloudy juice, concentrated fruit juice ,jam and other products. This production line is mainly composed of bubble cleaning machine, elevator, sorting machine, brush washing maching, cutting machine, pre-cooking machine, peeling and pitting machine, pulping machine, crusher, belt-type extractor , separator, evaporator,, sterilization machine ,filling machine and other equipment. The production line has advanced design concept is and high automation degree. The main equipments are made of high quality stainless steel, fully meet the health requirements of food processing.

* handling capacity :3 tons to 1500 tons / day.

* can handle fruits similar to mango, pineapple, etc..

* can use multistage bubble cleaning and cleaning

* use a belt press to deal with the pineapple to raise the juice yield.

* to complete the mango juice from Peel Pitting beater.

* low temperature vacuum concentration, to ensure flavor and nutrients, and greatly save energy.

* tube sterilization and aseptic filling, to ensure that the product is sterile.

*Automatic cleaning system.

*material contact parts are 304 stainless steel material, fully meet the requirements of food hygiene and safety.

Whatsapp/Line/Wechat/Mobile: 008618018622127 Welcome any inquiry!

Main Features

we take advantages of the comprehensive and technical cooperation with the Italian company partner, now in fruit processing, cold breaking processing, multi effect energy saving concentrated, sleeve type sterilization and aseptic big bag canning has made domestic and unmatched technical superiority. We can provide the entire production line processing 500KG-1500 tons of raw fruit daily according to the customers.

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of "Quality and Service Branding", after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

Whatsapp/Line/Wechat/Mobile: 008618018622127Welcome any inquiry!

General Introduction:

Shanghai JUMP Automatic Equipments Co., Ltd is the first company to manufacture complete food&beverage processing line in China and we are keeping leadership position in this industry for 30 years since 1986 when China first introduced technique from Italy/German and started to manufacture.

We are famous for tomato paste and concentrated apple juice processing line. We also have made brilliant achievements in other fruit& vegetable beverage equipments, such as:

1. Juice production line for orange juice, grape juice, jujube juice, coconut drink/coconut milk, pomegranate juice, watermelon juice, cranberry juice, peach juice, cantaloupe juice, papaya juice, sea buckthorn juice, orange juice, strawberry juice, mulberry juice, pineapple juice, kiwi juice, wolfberry juice, mango juice, sea buckthorn juice, exotic fruit juice, carrot juice, corn juice, guava juice, cranberry juice, blueberry juice, RRTJ, loquat juice and other juice drinks dilution filling production line

2. Can food production line for canned Peach, canned mushrooms, canned chili sauce, paste, canned arbutus, canned oranges, apples, canned pears, canned pineapple, canned green beans, canned bamboo shoots, canned cucumbers, canned carrots, canned tomato paste, canned cherries, canned cherry

3. Sauce production line for mango sauce, strawberry sauce, cranberry sauce, canned hawthorn sauce etc.

Solid Strength:

We has independent intellectual property rights of the equipments, including: large vacuum evaporation concentrating equipment (1000L-60000L/H), large sterilization equipment (tube and tube in tube type 1T/H-50T/H), large drying equipment (water evaporation quantity 100-10000T/H), aseptic filling equipment, and many advanced pretreatment equipment for different fruits. Among them, the concentrated equipment for juice and jam, with its high performance and ultra-low temperature , has gain high reputation in the industry; And large tube-in-tube sterilization equipment have gain major breakthrough in energy saving, saving 30% energy compared with the industry standard, which has owned the national patent (Patent No.: ZL 201120565107.2); Various types of advanced juicing and beating equipment have been ranking first for continuous 7 years regarding their quality and sales volume.

We grasped proficient technology and advanced biological enzyme technology, successfully applied in more than 120 domestic and foreign jam &juice production lines and we has helped client gain excellent products and good economic benefits.

Spray cleaning machine

Main characteristic:

1 Used to wash freshGuava, tomato, strawberry, mango, etc.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc.

Motor Power: 3KW

homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

CIP clean system

Semi-automatic cleaning system