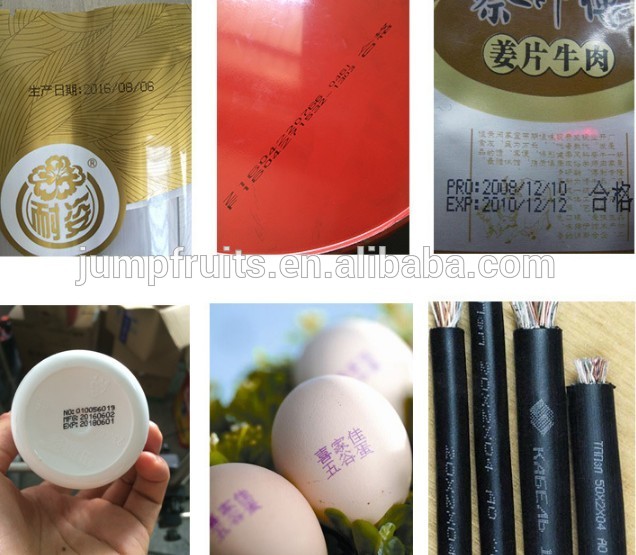

Industrial Inkjet Coding Machine

- Color & Page:

-

Multicolor

- Type:

-

Inkjet Printer

- Condition:

-

New

- Plate Type:

-

Screen Printer

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

A500

- Usage:

-

Bill Printer, Card Printer, Cloths Printer, Label Printer, Paper Printer, Tube Printer

- Automatic Grade:

-

Automatic

- Voltage:

-

AC 100V-240V

- Gross Power:

-

150W

- Dimensions(L*W*H):

-

420x320x535mm(mm)

- Weight:

-

20kg

- Certification:

-

CE Certification

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

Industrial inkjet coding machine

- Ink type:

-

Water-based Ink

- Media Type:

-

Flex

- Application:

-

glass,PVC, paper.Indoor Outdoor Advertisement

- Printhead:

-

DX5 Piezo-Electric Printhead

- Name:

-

High Definition Chines Handheld Portable Inkjet Printer

- Key words:

-

Small Character Inkjet coder Machine

- Ink:

-

3 Colors

- Print speed:

-

300m/min

- Print head:

-

Double

- 20 Set/Sets per Month industrial inkjet printing machine

- Packaging Details

- Carton

- Port

- Shanghai or customized

- Lead Time :

- 10 days after received the payment

Industrial inkjet printer / coding machine

Characteristics of the equipment of the inkjet printer

1. innovative uses Android operating system, unrivalled fluency and operation experience comparable to any tablet computer on the market, farewell to the tedious mouse of the jet printer, the industrial spray machine operated by the cell phone, and you deserve it.

2. completely liberated mouse and key operation, just touch the touch screen, every step of your way, it will respond in time.

3. true color high definition display, 1024*600 resolution, and more realistic icons.

4. perfect Sogou input method experience

5. innovative high analytical spray machine automatic cleaning system, so that you completely bid farewell to the difficult maintenance of the parsing machine, the spray head is easy to plug, the printing effect is good time and bad, one key cleaning spray head, farewell tedious maintenance steps

6. the rich external ports can realize a variety of expansion functions, such as database printing, networking printing, anti-counterfeiting code printing, etc.

7. the rich expansion function can connect 6 independent sprinklers, and each sprinkler can independently print different contents.

8. a machine can add three different colors of ink, and print three primary colors and print out color information or LOGO.

Air Blowing & Washing Machine

1 Used to wash fresh tomato, strawberry, mango, etc.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc.

Peeling, pulping & Refining Monobloc (Pulper)

1. The unit can peel, pulp and refine fruits together.

2. The aperture of strainer screen can be adjustable (change) based on customer’s requirement.

3. Incorporated Italian technology, high quality stainless steel material in contact with fruit material.

Belt press extractor

1. Widely used in extracting and dehydrating of many kinds of acinus, pip fruits, and vegetables.

2. the unit adopt advanced technology, big press and high efficiency, high degree of automatic, easy to operate and maintains.

3. the extraction rate can be get 75-85%(based on raw material)

4. low investment and high efficiency

Preheater

1. To inactivate enzyme and protect color of paste.

2. Auto temperature control and the out temperature are adjustable.

3. Multi-tubular structure with end cover

4. If the effect of preheat and extinguish enzyme failed or not enough, the product flow return to tube again automatically.

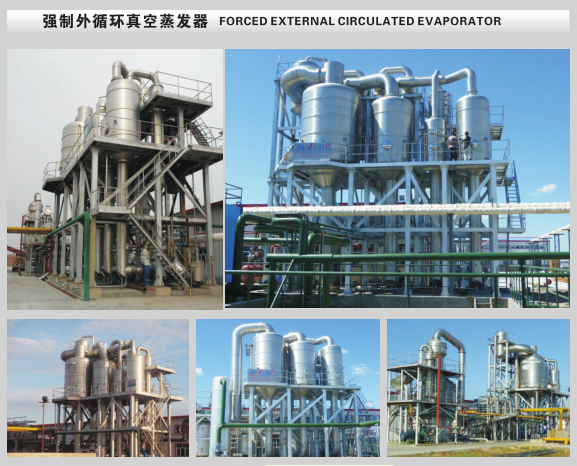

Evaporator

1. Adjustable and controllable direct contact heat treatment units.

2. Shortest possible residence time, presence of a thin film along the entire length of the tubes reduces holdup and residence time.

3. Special design of liquid distribution systems to ensure correct tube coverage. The feed enters at the top of the calandria where a distributor ensures film formation on the inside surface of each tube.

4. The vapor flow is co-current to the liquid and the vapor drag improves the heat transfer. The vapor and the remaining liquid are separated in a cyclone separator.

5. Efficient design of separators.

6. Multiple effect arrangement provides steam economy.

Tube in tube sterilizer

1. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc.

2. Incorporated Italian technology and conform to Euro-standard

3. Great heat exchange area, low energy consumption and easy maintenance

4. Adopt mirror welding tech and keep the smooth pipe joint

5. Auto backtrack if not enough sterilization

6. CIP and auto SIP available together with aseptic filler

7. Liquid level and temp controlled on real time

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu