*Put the machine onto bottom iron support

*Bind foot stool with iron bar on the bottom support by iron wire tightly.

*Use PE film to Shrink the machine well

*Wrapped the plywood case with metal frame

*Deliver them by sea or by air

Full Automatic Multi Lanes Honey / ketchup / jam / Liquid Packing Machine

- Type:

-

Multi-Function Packaging Machine

- Packaging Material:

-

plastic

- Packaging Type:

-

Bags

- Function:

-

FILLING, Sealing

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

None

- Showroom Location:

-

None

- Condition:

-

New

- Application:

-

Food, Beverage, MEDICAL, Chemical

- Automatic Grade:

-

Automatic

- Driven Type:

-

Electric

- Voltage:

-

380V

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

Jumpfruits

- Dimension(L*W*H):

-

depends on the capacity

- Certification:

-

CE

- After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

- Warranty:

-

1 Year

- Key Selling Points:

-

Easy to Operate

- Marketing Type:

-

New Product 2020

- Machinery Test Report:

-

Provided

- Video outgoing-inspection:

-

Provided

- Warranty of core components:

-

5 years

- Core Components:

-

Motor

- Product name:

-

Full Automatic Multi Lanes Liquid Packing Machine

- Usage:

-

Honey, cream,ketchup ,sauce, jam sachet pacakging

- Bag type:

-

4 Sides Seal

- Machine type:

-

Multi-lanes high efficiency

- Packing speed:

-

120-320bags/min

- Packing material:

-

Laminated Film

- Film material:

-

Aluminum Plastic Film

- 5 Set/Sets per Month Full Automatic Multi Lanes Liquid Packing Machine

- Packaging Details

- wooden case

- Port

- Shanghai

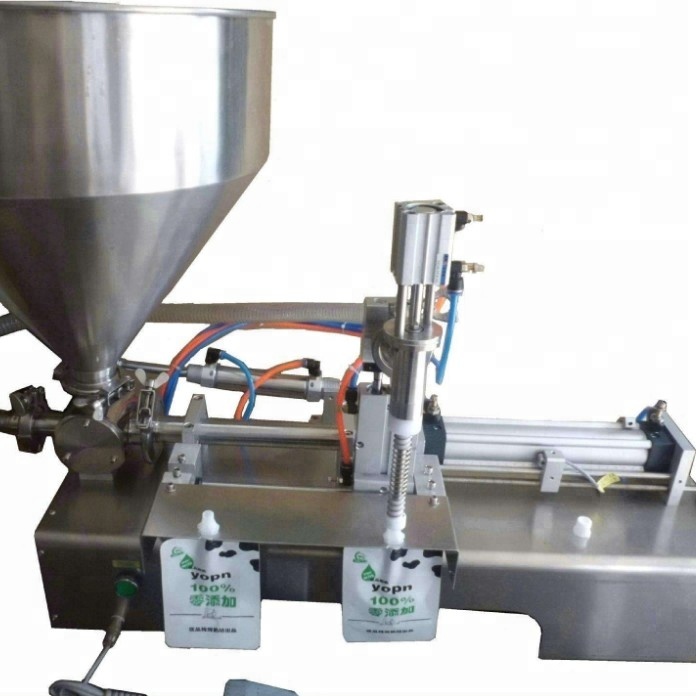

- Picture Example:

-

- Lead Time :

-

Quantity(Sets) 1 – 1 >1 Est. Time(days) 60 To be negotiated

Round Corner Full Automatic Multi Lanes Stick Bag Honey Packing Machine.

Applicable:

This machine is widely used in pharmaceutical, food and chemical industry.It is suitable for packing all kinds of liquid material, like sauce,paste,ketchup,etc.

Machine Function:

1)Multi-lines liquid packing machine adopt advanced PLC and photoelectric control system.

2)Be able to weight, bag-making, filling, sealing, cutting, lot number, cutting easy tearing notch etc. Automatically, it can be operated by one person only.

3)To has color control system which can get the complete trade mark design.

4) No need to change the mould if you want to change the length of board, just adjust the speed governor.)

5) Advantage: to operate simply; high accuracy; save electricity & speed fast.

6) Optional machine: electrical black ink coding machine and rotating machine

7) Operation manual and warranty card will be delivered to the clients with machine

Full Features:

1) Be able to weight, bag-making, filling, sealing, cutting,lot number automatically.

2) It has color control system which can get the complete trade mark design(photoelectricity control system).

3) The machine fix stepper motor controller,its advantage is precise,needless to adjust other parts

4) Intelligent temperature control by temperature controller to make heat balance better.use bilingual

display screen control system and stainless steel cabinet

5) Fine packaging performance ,low noise ,clear sealing texture and strong sealing performance

6)With printer (to be able to code the date and batch number) and rotating blade(be able to adjust the length of bag and shape of bag notch edge packing

7).Round corner design can protect customers from being scratched to ensure the safety of consumers.

8).Special designed stick bag with small package opening, which can avoid product spill and easy to control.

9)Two easy slit notch on the bag to make it easier to open.

10)this is a new and popular bag type at present.with round corner

11). Special design of round corner avoids hurting finger, especially for kids. This design is very nice and applied to many domestic and overseas factories. It is a trend in stick bag.

12) Two easy tear notch is novelty and humanized. It is easy to tear.

13) Special design of volume cup keep the accuracy and the integrity of matirail by its gravity motion.

14) Servo motor makes the operation much more stable.

15) Machine operation is controlled by PLC system. Automatic adjustment of bag length and filling range is displayed by touch screen. It can be designed as your local language.

16) Machine house, our filler distributor and other parts are 304SS (18/10) stainless steel material against rust.

17)Photocell controller of cursor positioning system test film operation to make film moving not out

of track.

18)The cutter is pneumatic, so that it will be very sharp.

|

Model

|

JPDXD-Y4/6/8

|

|

Name

|

Multi lanes packing machine

|

|

Machine speed

|

120-320bags/min

|

|

Bag size

|

(L)30-140 mm (W) 25-60/55mm

|

|

Maximum film width

|

480/680/880/1080mm

|

|

Film Material

|

Laminated film, laminated paper film, Pure Aluminum film

|

|

Bag type

|

4-side sealing

|

|

Voltage

|

AC380V/50HZ

|

|

Total Power

|

2.7KW

|

|

Measuring range

|

1-30ml

|

|

G.W

|

800KG

|

|

Control system

|

Taiwan Delta PLC control system

|

|

Weighting mold

|

Electronic Pump

|

|

Machine material

|

Stainless Steel 304(SS304)

|

|

Air source

|

0.24cbm/min.,0.6Mpa

|

|

Screen

|

Full touching screen (every step can be set by touching screen)

|

|

Function

|

Be able to weight, fill, make the bag, print manufacture date and expiry date and batch number, seal, cut off automatically

|

Package and Shipment.

1.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

2.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

3.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.