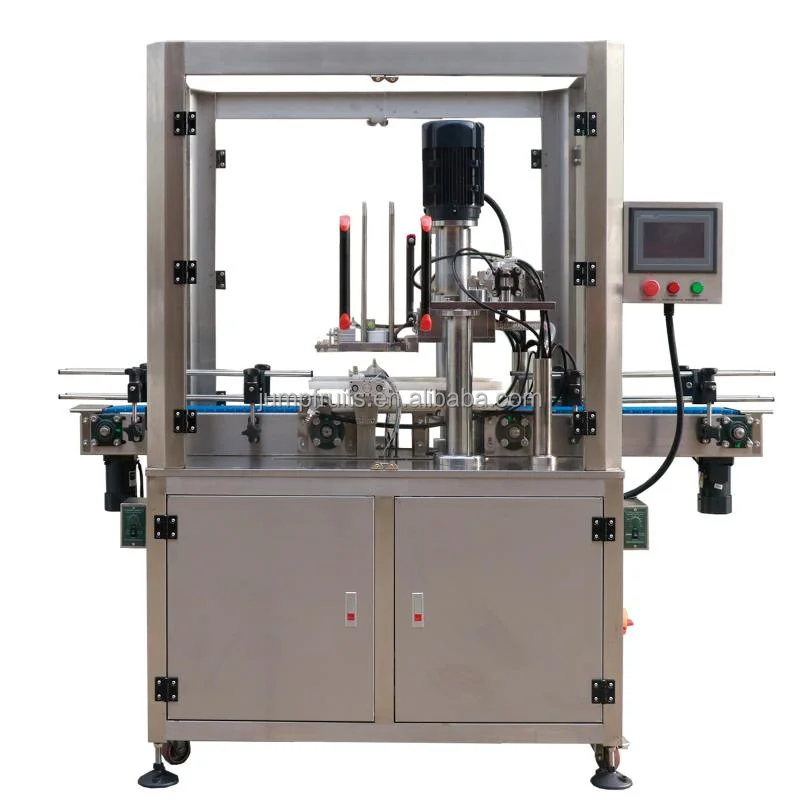

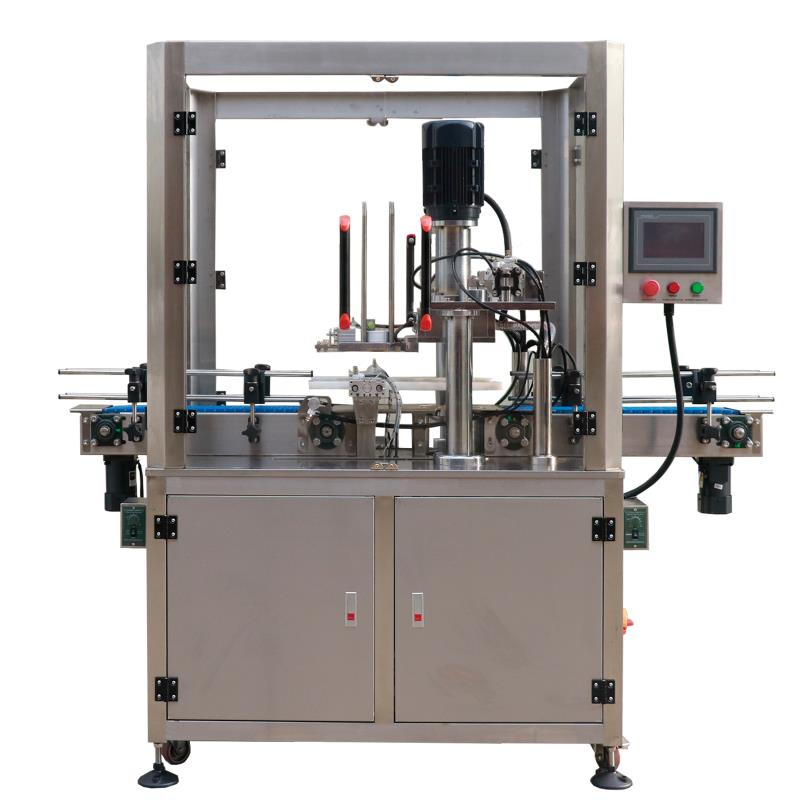

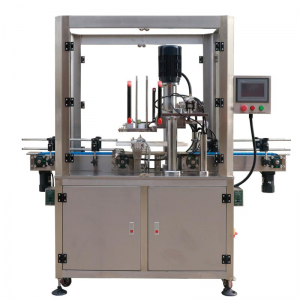

Full-automatic High Speed Vacuum Sealing Machine For Tin Cans And Bottles

Customizable High-efficiency Full-automatic

High Speed Vacuum Sealing Machine For Tin Cans And Bottles

Equipment Performance Description And Characteristics

1. The sealing diameter is φ40~φ127mm, and the sealing height is 60~200mm;

2. Two working modes are available: vacuum and nitrogen filling and sealing and vacuum sealing;

3. In the vacuum and nitrogen filling mode, the residual oxygen content after sealing can reach 3% or less, and the maximum speed can reach 6 cans/min (the speed is in accordance with the size of the cans).

The value standard of residual oxygen is related)

4. Under vacuum sealing mode, it can reach 40kpa~90Kpa negative pressure value, and the speed is 6 to 10 cans/min;

5. The overall appearance material is mainly made of stainless steel 304, with a thickness of 1.5mm;

6. The plexiglass material is made of imported acrylic, the thickness is 10mm, and the high-end atmosphere;

7. It adopts 4 hobs to rotate and seal the can body, and the sealing performance index is excellent;

8. Using PLC intelligent programming and touch screen control, it is convenient and simple to use and set up;

9. There is a cover missing alarm prompting function to ensure the efficient and uninterrupted operation of the equipment;

10. Set up no lid, no sealing and shutdown for failure detection, effectively reducing equipment failures;

11. The capping device can be capped with 200 caps (one tube) at a time;

12. The mold needs to be replaced to replace the caliber, and the replacement time is about 40 minutes;

13. Change the caliber to be replaced: pressure head + clamp + lid lowering device, cans and lids of different materials need to be replaced with sealing rollers;

14. Change the sealing height of the can without changing the accessories. The hand screw design is adopted to effectively reduce the failure. The adjustment time is about 5 minutes;

15. The sealing effect is tested by strict inspection methods before delivery and use to ensure product quality;

16. The defective rate is extremely low, iron cans are less than one ten thousandths, plastic cans are less than one thousandth, and paper cans are less than two thousandths;

17. The indenter adopts chromium 12 molybdenum vanadium quenching treatment, the hardness exceeds 50 degrees, and the service life exceeds 1 million cans;

18. The roller adopts the roller imported from Taiwan, and the hob material is SKD Japanese special mold steel, with a life span of more than 5 million sealing times;