Full Automatic Candied Fruit Dried Fruit Production Line / Candied Fruit Processing Machine

- Applicable Industries:

-

Food & Beverage Factory

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

jumpfruts

- Model Number:

-

cts11223

- Type:

-

turn key solution

- Voltage:

-

380V

- Power:

-

100KW

- Weight:

-

15T

- Dimension(L*W*H):

-

adjusted based on your factory design

- Certification:

-

CE ISO

- Year:

-

2019

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Field installation, commissioning and training

- Product name:

-

dried fruit processing machines

- Production capacity:

-

0.3-10T/H

- Material:

-

SUS304

- Advantage:

-

life-long after-sales Service

- Application:

-

Kinds OF FRUIT

- Feature:

-

Turn Key Project

- Supply Ability:

- 10 Set/Sets per Month dried fruit processing machines

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.Mobile/whatsapp:+8613681836263

- Port

- Shanghai Port

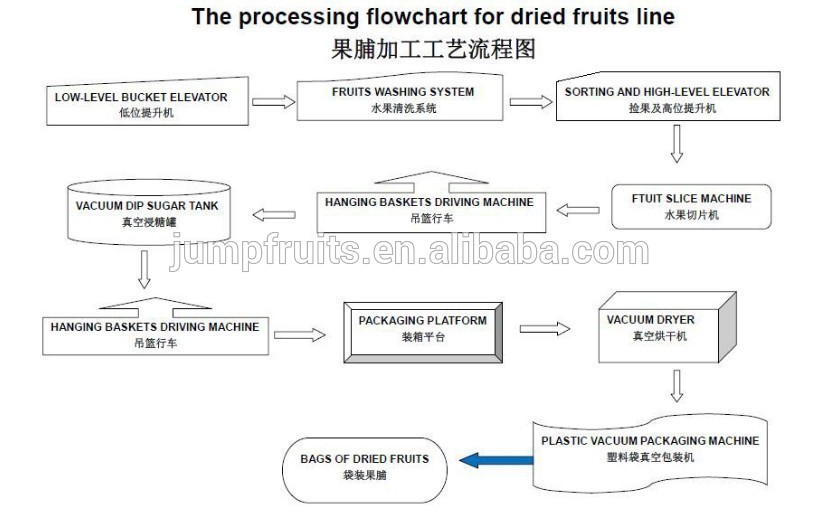

The modern mechanized production process of candied fruit candied fruit (for reference only, can be designed according to different processes):

Raw fruit – cleaning – peeling / enucleation / slicing / dicing – pre-cooking – dehydration – vacuum infiltration – drying – packaging – finished products.

1. Scope of application:

Hefei calf vacuum infiltration equipment can be applied to apple, pear, apricot, plum, peach, papaya, sweet potato, cantaloupe, lemon, kiwi, pineapple, red dates, dragon fruit, hawthorn, plum, kumquat, mango, blue plum Hundreds of fruit and vegetable agricultural products such as potatoes. Complete the process of soaking sugar, soaking salt, dipping and soaking in the production and processing of preserves, preserves, Chinese herbal medicines and pickles.

The complete production line equipment is suitable for large-scale mechanized production of users. The raw fruit processing capacity ranges from 5 tons/day to 40 tons/day, which is more suitable for users of local agricultural products.

Fruits made from the fruit production line, kiwi fruit products made from the fruit production line

2. System composition:

The main equipment of the candied fruit production line includes: washing machine, fruit and vegetable peeling machine, slice-cutting machine, vacuum infiltration system, continuous pre-cooking machine, drying box and so on. Through the above equipment, complete mechanized production of candied fruit can be realized

Whatsapp/Wechat/Mobile: 008613681836263 Welcome any inquiry!

Candied production line features:

1. Compared with the traditional method, it saves a lot of labor costs (mainly in the pre-treatment of fruits and vegetables in the process of peeling, saving 10-30 people);

2. Compared with the traditional method, the production efficiency is greatly improved (mainly in the vacuum infiltration process, which is 5-20 times faster than the traditional soaking method);

3. Compared with the traditional method, it greatly increases the health and safety of food processing and increases the yield of fruits and vegetables;

4. Compared with the traditional method, the work accident accident caused by manual peeling and nuclear removal is greatly reduced, and the loss of fruit color and nutrient content is reduced;

5. Vacuum infiltration of sugar is carried out by sanitary pipelines to prevent external pollution. The unit can be vacuumed, heated, pressurized, and insulated. It can also be rapidly cooled and used in one machine.

6. The complete set of equipment is made of 304/316L food grade stainless steel, which is the development direction of modern production and large-scale production of candied fruit candied enterprises;Product Application

Raw materials: fresh fruit (mano,apple, kiwi,apricot,grape,olive,prune)

The final product: dried mango,apple ,kiwi, apricot,raisin,olive,prune,and so on

Fresh tomato treatment: 0.5-500 tons/hour of fresh fruits(per customer requirement)

Tomato paste output: 0.1-100 tons/hour(depends on fruit type, brix,etc.)

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.