Factory price watermelon juice processing machines industry production

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JPFXG-5055

- Type:

-

watermelon juice processing line

- Voltage:

-

220V/380V

- Power:

-

2.2kw

- Weight:

-

150kg

- Dimension(L*W*H):

-

900*460*740mm

- Certification:

-

CE/ISO9001

- Warranty:

-

1 Year warranty,life-long aftersell service

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

watermelon juice machine

- Application:

-

produce watermelon juice,pulp and puree

- Feature:

-

turnkey solution,from A to Z service

- Name:

-

watermelon juice production line

- Capacity:

-

reasonable design for customer,100kg/H to 100T/H

- Scale:

-

home scale and commercial scale

- Function:

-

Multifunctional

- Material:

-

SUS304 Stainless Steel

- Usage:

-

Commercial Usage

- Item:

-

Automatic Fruits Juicer Machine

- 20 Set/Sets per Month

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion.Fumigation-free package helps the smooth customs clearance.The big size machine will be fixed in container without package.

- Port

- shanghai port

- Lead Time :

- 2-3 months

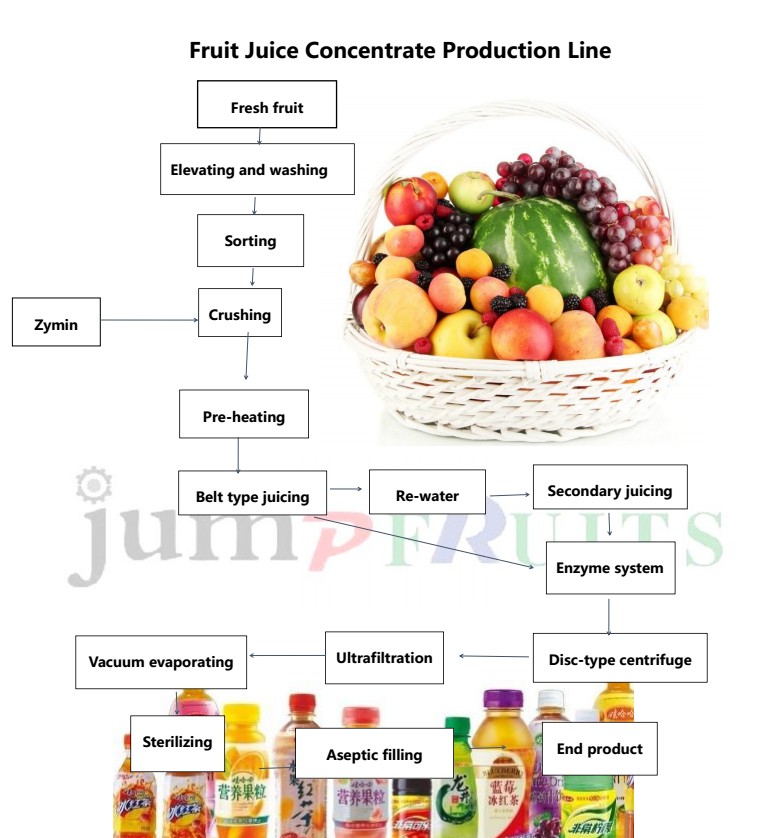

Main System introduction:

Water treatment:

Raw water tank → raw water pump → quartz sand filter → activated carbon filter → PH adjusting device → precision filter → RO device → ultraviolet sterilizer → pure water tank → pure water pump

Deployment and sterilization system:

Cleaning → beating → enzymolysis → filtration → sugar cans → beverage pump → syrup filter → dispensing tank → beverage pump → double filtration → ultra-high temperature sterilizer → high sterile insulation tank → CIP cleaning device → CIP return pump

Filling and packaging system:

Washing cans → Filling and Sealing 2 in 1 unit → Turn cans → Conveying system → Tunnel sterilization → Strong drier → Inkjet printer → Turn cans → Manual packing

Related beverage machinery and equipment:

Sterilization tank, mixing tank, direct cooling tank, hot and cold tank, sugar pot, the reaction plate heat exchanger, filtration equipment, horizontal sterilization pot, ultra-high temperature instantaneous sterilization machine, enrichment equipment, CIP cleaning equipment , Beverage pump, filter equipment, water softening and processing equipment, beater, colloid mill, juice equipment, homogenizer, vacuum degassing tank, multi-function extraction tank, filling equipment, sanitary valves etc.

Characteristics:

1.freely placed

2.Convenient maintenance

3.steady performance

4.easy operate

To design watermelon juice/pulp/puree processing line of energy and capital intensive. Just free free to contact 008618018622127

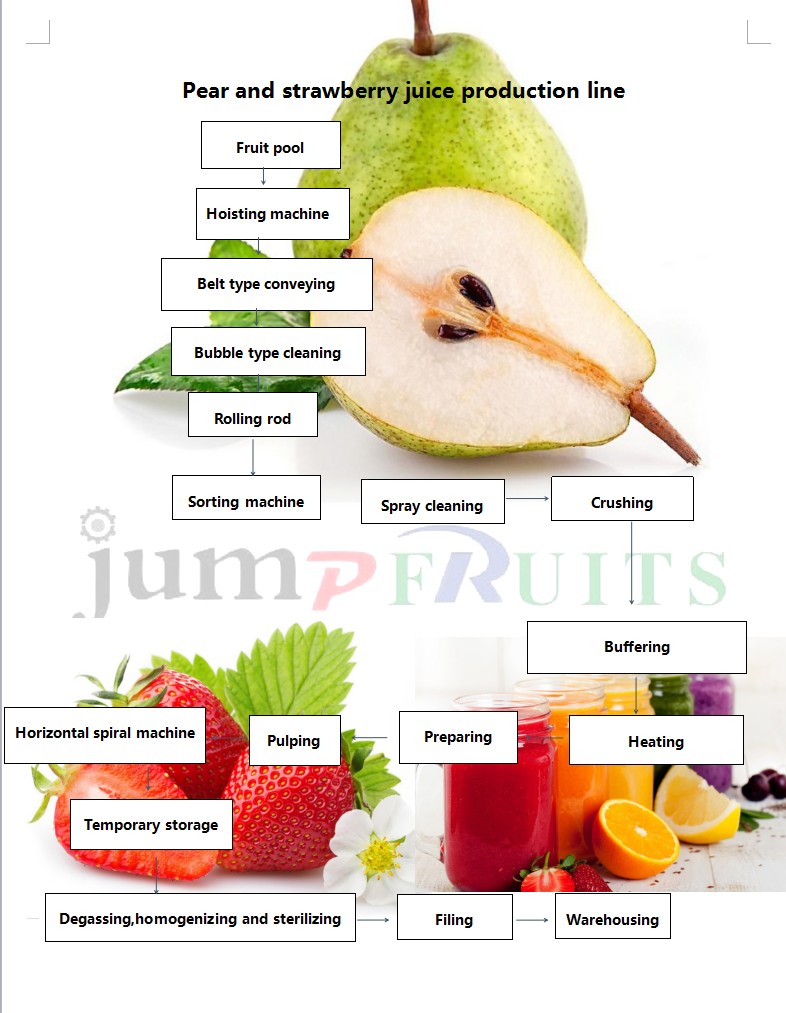

Shanghai JUMP Automatic Equipments Co., Ltd, is keeping leadership position in the tomato paste and concentrated apple juice processing line. We also have made brilliant achievements in other fruit& vegetable beverage equipments, such as:

1. Juice production line for orange juice, grape juice, jujube juice, coconut drink/coconut milk, pomegranate juice, watermelon juice, cranberry juice, peach juice, cantaloupe juice, papaya juice, sea buckthorn juice, orange juice, strawberry juice, mulberry juice, pineapple juice, kiwi juice, wolfberry juice, mango juice, sea buckthorn juice, exotic fruit juice, carrot juice, corn juice, guava juice, cranberry juice, blueberry juice, RRTJ, loquat juice and other juice drinks dilution filling production line

2. Can food production line for canned Peach, canned mushrooms, canned chili sauce, paste, canned arbutus, canned oranges, apples, canned pears, canned pineapple, canned green beans, canned bamboo shoots, canned cucumbers, canned carrots, canned tomato paste, canned cherries, canned cherry

3. Sauce production line for mango sauce, strawberry sauce, cranberry sauce, canned hawthorn sauce etc.

We grasped proficient technology and advanced biological enzyme technology, successfully applied in more than 120 domestic and foreign jam &juice production lines and we has helped client gain excellent products and good economic benefits.

No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

Watermelon juice production line

Our Advantages:

1.Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop services, from your warehouse designing(water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

2.15 years export experience, easily transport cargo to your door

3.customized service, we will try our best to meet your requirement.

4.Quality guarantee: 12 months. After that, engineers also available on your traval expense and spare parts cost.We offer life-long after-sale service.

Main advantages of our system line:

1. High production speed achieved by a newly designed head system (single head or twin heads available), improved reliability from a fully PLC controlled self diagnostic operational mode.

2. Greater versatility by meeting various packing standards with different products.

3 Coordinates well with the tube in tube sterilizer, if some malfunction with the filler, the product will be automatic flow back into the buffer tank before the UHT sterilizer.

4. The use of a hermetically sealed empty bag ensures the bag will remain sterile before it is filled.

5. High pressure saturated steam is used for sterilization of the fitment, cap and exposed portion of the filler prior to each filling cycle. NO CHEMICALS are required.

6. The sealing of the fill valve on the interior of the fitment keeps product completely away from the package sealing area.

7. The hermetic heat sealing of the fitment provides a tamper evident closure and a superior oxygen barrier.

8. The overall aseptic design of the filler allows uninterrupted. Operation throughout a complete tomato/fruit season, maximizing your plant’s efficiency

9. CIP and SIP available together with tube in tube sterilizer

Beverage equipment & production line

* Production output from 1000-35000 bottles per hour.

* Packaging forms include cans, PET bottles, glass bottles, roof bags, sterile soft packs

* Flexible production line configuration, according to customer needs of different end products, you can configure different functions of the device

* Available basket-type, continuous counter-current and other means of extraction

* The entire line of modular design, a combination of different processing technology

* High degree of automation, saving labor

* With cleaning system, easy to clean

* System materials contact part of all 304 stainless steel, in full compliance with food hygiene and safety requirements

Package: glass bottle, PET plastic bottle, cans, aseptic soft package, roof pack 2L-220L sterile bag, carton package, plastic bag, 70-4500g tin can.

Whatsapp/Line/Wechat/Mobile: 008618018622127 Welcome any inquiry!

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of "Quality and Service Branding", after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

Whatsapp/Line/Wechat/Mobile: 008618018622127 Welcome any inquiry!

We

Products categories

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu