factory low price Canned Mushrooms Equipment - Soft candy machine – JUMP

factory low price Canned Mushrooms Equipment - Soft candy machine – JUMP Detail:

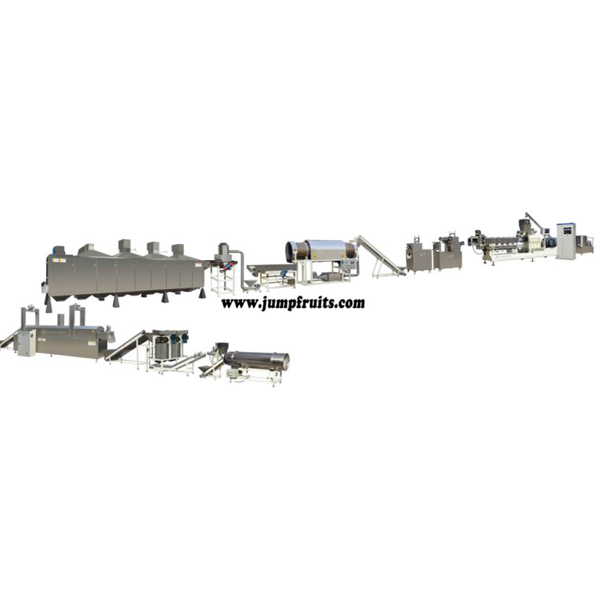

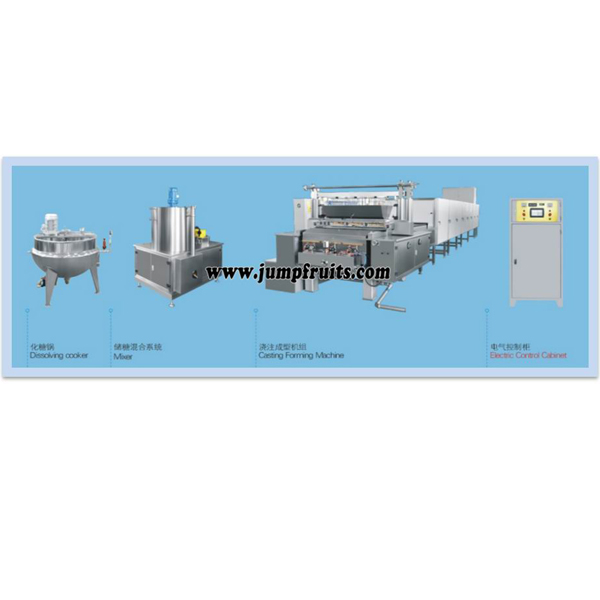

Soft candy machine and production line process flow:

(1)sugar dissolving; (2) sugar conveying; (3)keepng warm in storage tank; (4)mixing for flavor and sugar; (5)syrup into hopper; (6) depositing (contering filling )forming; (7)cooling into tunnel; (8)demoulding and cooling with conveying out; (9) Packing.

Candy (English: sweets) can be divided into hard candy, hard sandwich candy, milk candy, gel candy, polished candy, gum based candy, inflatable candy and pressed candy. Among them, hard candy is a kind of hard and crisp candy with white granulated sugar and starch syrup as the main materials; hard sandwich candy is hard candy with filling core; milk candy is made of white granulated sugar, starch syrup or other sugar, oil and dairy products as the main materials, with egg white quality no less than 1.5%, fat not less than 3.0%, with special creamy flavor and burnt flavor; Gel candy is a soft candy made of edible gum (or starch), white granulated sugar and starch syrup (or other sugar) as main material; polished candy is a solid and solid candy; gum based candy is a chewing or bubbling candy made of white granulated sugar (or sweetener) and rubber based material; inflatable candy is a candy with fine, uniform bubbles inside the sugar body. Pressed candy is a kind of candy which is granulated, bonded and pressed.

| Soft candy equipment Major parameter | |||||

|

1) |

Capacity | 150kgs /h | ( speed is adjstable ) | ||

|

2) |

Max candy weight | 26g | |||

|

3) |

Depositing speed | 45-50n/min | |||

|

4) |

Working Environment temperature | <25℃ | |||

|

5) |

Humidity |

55% |

|||

|

6) |

Steam requirement | 500kg/h , 0.5-0.8MPa | |||

|

7) |

Air compress | :0.25m3/min,0.4~0.6MPa | |||

|

8) |

Power | 18kW/380V/50HZ | |||

|

9) |

Length | 18m | |||

|

10) |

Weight | 3000kgs | |||

Product detail pictures:

Related Product Guide:

With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for factory low price Canned Mushrooms Equipment - Soft candy machine – JUMP , The product will supply to all over the world, such as: Provence, Accra, Hungary, Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.