1, using a special plastic material, has a strong anti-corrosion ability, can absolutely guarantee the separation of food.

2, according to the shape of the customer’s request, you can customize the biscuit abrasive.

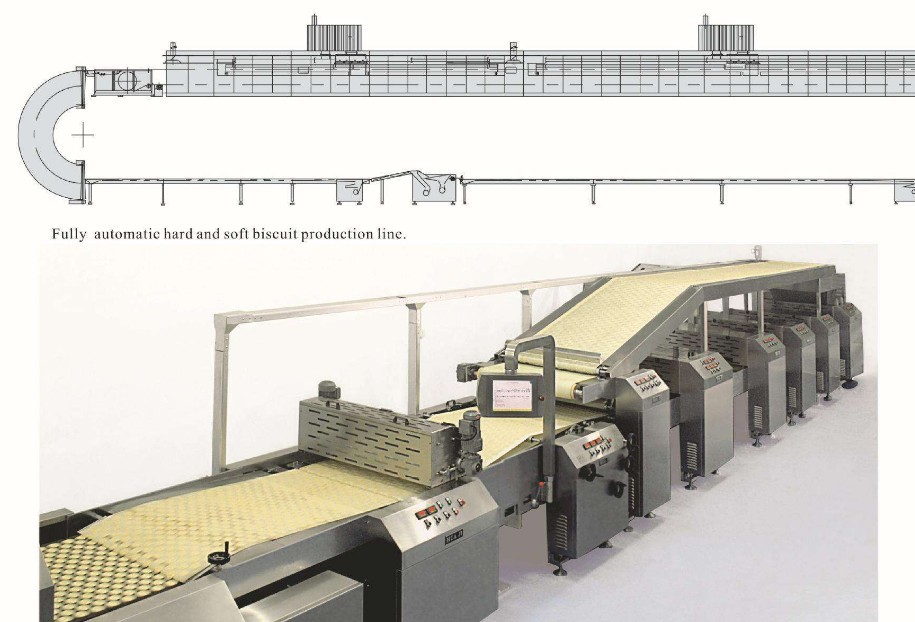

A: Introduction to the biscuits production line

This type Automatic Biscuit Production Line is developed by the company’s digestion and absorption of Japanese technology. The equipment has a novel design, a compact structure, and a high degree of automation, from feed rolling, molding, waste recycling, drying, fuel injection, and cooling. Fully automatic one-time completion, the company provides users with hundreds of molds and dozens of process recipes. By changing the molds and process recipes, it can produce a variety of high-end biscuits popular on the market, such as cream biscuits, sandwich biscuits, ultra-thin biscuits. , soda crackers, animal biscuits, multi-dimensional cookies, vegetable biscuits, etc.

B: Technical Parameters

|

Host Model

|

LZB-400

|

|

Voltage

|

380v/50hz

|

|

Installed power

|

120KW (Real power consumption is 110KW)

|

|

Baking temperature

|

200-300℃

|

|

Working Width

|

950mm

|

|

Production capacity

|

150-200kg/h

|

|

Production line length

|

43m

|

C: Cookies process flow:

Pretreatment of raw materials – dough preparation – rolling dough – cake pressing – baking – fuel injection – cooling

D: Features

1, biscuit forming host: The equipment consists of three parts: leather making, molding and recycling of residual material;

2, one-time roll forming, high molding rate, good molding quality.

3, when changing the product specification, only need to change the impression roller.

4, dry box way sub-section assembly, easy to install and transport.

5, drying box: mesh belt furnace with stainless steel mesh to bring products, baking effect is good.

6. Injector adopts frequency converter to control speed, stable speed and good energy-saving effect.

7, fuel injector: injector head angle can be adjusted.

8. The part of the machine that contacts food is stainless steel, which meets the food hygiene requirements.

1, using a special plastic material, has a strong anti-corrosion ability, can absolutely guarantee the separation of food.

2, according to the shape of the customer’s request, you can customize the biscuit abrasive.

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

2.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

3.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.