dry pulverizer machine for a fruits and vegetable fruit drying machine vegetables

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location:

-

None

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

5 years

- Core Components:

-

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Type:

-

fruits and vegetables dehydration machines

- Voltage:

-

380V

- Power:

-

86 kw

- Weight:

-

1200kg

- Dimension(L*W*H):

-

10000*1200*2100

- Certification:

-

CE ISO

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

fruit and vegetable drying machine

- Production capacity:

-

0.5-500T/H

- Function:

-

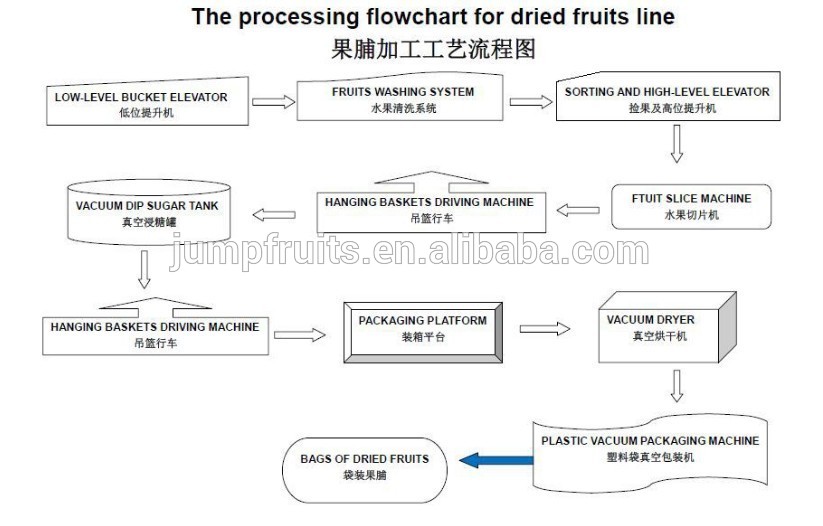

dried fruit processing line

- Usage:

-

dried fruits processing and packing

- Raw material:

-

fresh mango, pear, lemon, apple, pineapple

- Application:

-

Pineapple, mango, apricot, grape

- Capacity:

-

500-30000kg/h

- Name:

-

industrial fruit drying machine

- Feature:

-

Easy Operation

- 10 Set/Sets per Month fruit and vegetable drying machine

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- Shanghai Port

Shanghai Jump automatic equipment Co., Ltd. Is modern high-tech joint-stock enterprises, formerly known as Shanghai Qianwei machinery plant, professional engaged in whole plant equipment design, manufacturing, R & D and turnkey project for juice and jam, tropical fruit processing, heat canned fruit juice drinks, tea drinks, yogurt, cheese and liquid milk dairy processing . The employee quality of the company is excellent, the backbone of the engineer and the core technology R & D personnel directly from the original Qianwei machinery factory, also has a number of food engineering and packaging machinery professional master and doctoral, fully equipped with the whole line project design and development, production and manufacture, installation and commissioning, technical training and after-sales service, etc. the comprehensive ability.

Our main production line

1Tomato paste / puree / jam / concentrate, ketchup, chilli sauce , other fruit & vegetables sauce / jam processing line

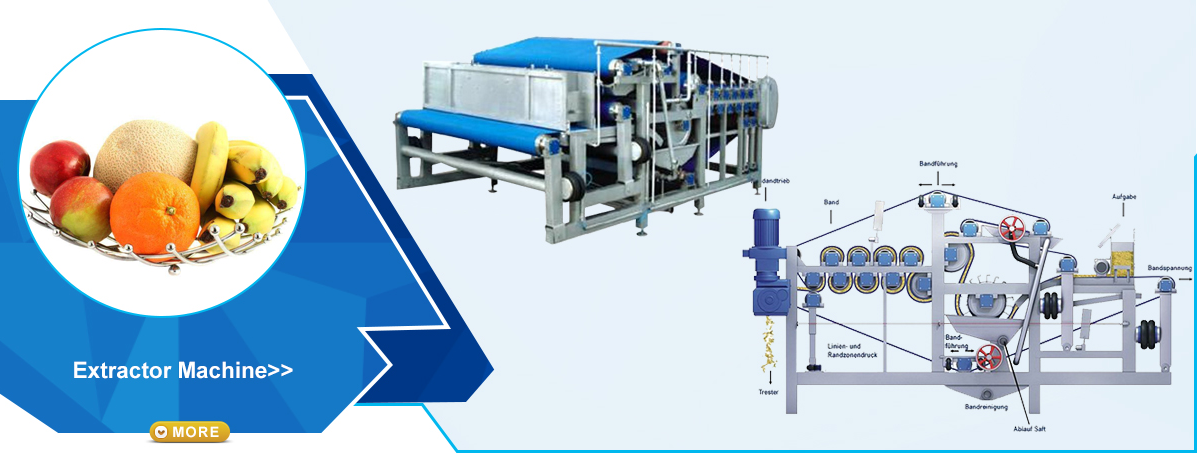

2Fruit & vegetables ( orange , guava, cirtrus, grape, pinapple, cherry, mango, apricot.etc. ) juice and pulp processing line

3Pure, mineral water, Mixed beverage, drink (soda, Cola, Sprite, carbonated beverage, no gas fruit drink, herbal blend drink, beer,cider, fruit wine .etc. ) production line

4Canned fruit & vegetables ( tomato, cherry, beans, mushuroom, yellow peach, olives, cucumber, pineapple, mango, chili, pickles and so on. ) production line

5Dried fruit & vegetables ( dried mango, apricot, pineapple, raisin, blueberry .etc. ) production line

6Dairy (UHT milk, pasteurized milk, cheese, butter, yogurt, milk powder, margarine, ice cream)production line

7Fruit and vegetable powder (Tomato, pumpkin, cassava powder, strawberry powder, blueberry powder, bean powder, etc. ) production line

8Leisure snack (Dried freeze-dried fruit, puffed food, french fried potato chips, etc. ) production line

This fruit processing line is suitable for dried fruit,such as,dried apricot,mango, pineapple, stawberry, blueberry, grape,raisin,olive,prune,and so on.

Apricot drying machine Features

1, the drying strength, due to the highly dispersed material in the air stream, the entire surface area of the particles is extremely dry and effective area.

2, short drying time

3, air dryer structure is simple, small footprint, easy to build and repair.

4, large capacity, high thermal efficiency. Thermal efficiency up to 60% when drying unbound water.

5, dryer to achieve a “zero horizontal thrust”, greatly reducing the wear and tear of the retaining wheel, cylinder running smoothly and reliably;

6, the dryer adopts “self-aligning roller device”, so that the support roller and rolling ring always linear contact, thus greatly reducing the wear and tear and power loss.

7, box dryer adapted to breathable sheet, strip, granular material drying. For the requirements of low drying temperature, long drying time of the material unique advantages.

Pre-sales service

We can suggest customer the most suitable machine according to their formula and Raw material. “Design and development”, “manufacturing”, “installation and commissioning”, “technical training” and “after sales service”. We can introduce you supplier of raw material, bottles, labels etc. Welcome you to our production workshop to learn how our engineer produce. We could customize machines according to your real need, and we could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

After-sale service

1.Installation and commissioning: We will send experienced engineering and technical personnel to be responsible for the installation and commissioning of the equipment until the equipment is qualified to ensure that the equipment is in time and put into production;

2.Regular visits:To ensure the long-term stable operation of the equipment, we will be based on customer needs, provide one to three times a year to come to technical support and other integrated services;

3.Detailed inspection report: Whether the inspection regular service, or the annual maintenance, our engineers will provide a detailed inspection report for the customer and the company reference archive, in order to learn the equipment operation at any time;

4.Fully complete parts inventory: In order to reduce the cost of parts in your inventory, provide better and faster service, we prepared a complete inventory of parts of equipment, to meet customers possible period of want or need;

5.Professional and technical training:In order to ensure the performance of the customer’s technical personnel to become familiar with the equipment, correctly grasp the equipment operation and maintenance procedures, in addition to install on-site technical training. Besides, you also can hold all kinds of professionals to the factory workshops, to help you faster and more comprehensive grasp of technology;

6.Software and consulting services:In order to allow your technical staff to have a greater understanding of the equipment related counseling, I will arrange to send the equipment regularly sent to the advisory and latest information magazine.No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.