Complete Automatic Peanut / Walnut / Soy Milk Blending Machine

- Applicable Industries:

-

Food & Beverage Factory

- After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

- Brand Name:

-

jumpfruits

- Voltage:

-

380V

- Power:

-

120kw

- Dimension(L*W*H):

-

depends on capcity

- Weight:

-

20T

- Certification:

-

SGS

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Field installation, commissioning and training

- Machinery Test Report:

-

Provided

- Video outgoing-inspection:

-

Provided

- Warranty of core components:

-

1 Year

- Core Components:

-

Pressure vessel

- Key Selling Points:

-

Automatic

- Product name:

-

soy milk production line

- Production capacity:

-

100kg-2T/H

- Material:

-

SUS304

- Function:

-

whole processing line

- After-sales Service:

-

overseas engineer service available

- Advantage:

-

life-long after-sales Service

- Feature:

-

High Efficiency

- Supply Ability:

- 30 Set/Sets per Month soy milk machine

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- Shanghai port

- Lead Time :

-

Quantity(Sets) 1 – 1 >1 Est. Time(days) 30 To be negotiated

Process flow:

Soybean Dry Bean Lifting System – Soy Soaking System – Soybean Pulping System – Sugar – Soy Milk Mixing System – Sterilization and Homogenization – Soy Milk Filling Line – Post-Bacterial Pasteurization System

Advantages:

1. Users can design special requirements

2. In the same production line can produce different end products

3. A short incubation time

4. Can be accurately added and mixed aromatic substances

5. high Yield, low loss

6. Application of high technology to save energy 20%

7. The entire production process monitoring systems

8. Image, intuitive display, print all process parameters

Whatsapp/Wechat/Mobile: 008613681836263 Welcome any inquiry!

UHT milk sterilizer machine

1 Capacity of plant: 2T-300T/D

2 Products type: 1 or 2 or more kinds.

homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

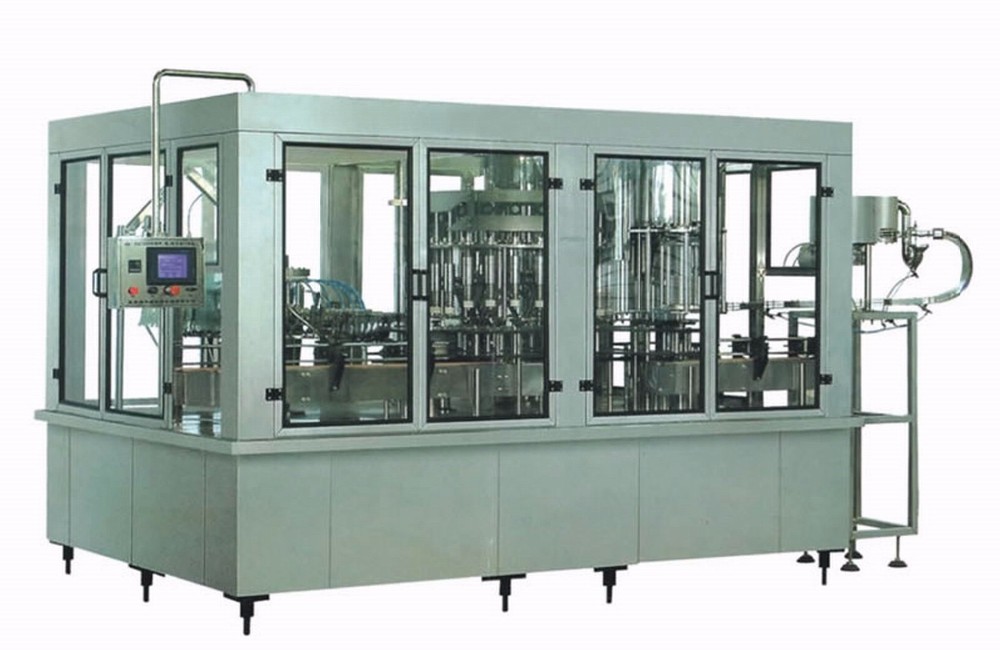

Filling maching

Specially suitable for tomato paste, mango puree and other viscous product.

35-50 bottle per min

Filling sachet valume:10-500g