China Manufacturer for Banana Chips Fryer - Peach / Cucumber Canned Production Line – JUMP

China Manufacturer for Banana Chips Fryer - Peach / Cucumber Canned Production Line – JUMP Detail:

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JPF-GT1289

- Type:

-

whole production line

- Voltage:

-

220V/380V

- Power:

-

0.75kw

- Weight:

-

600kg

- Dimension(L*W*H):

-

1380*1200*2000mm

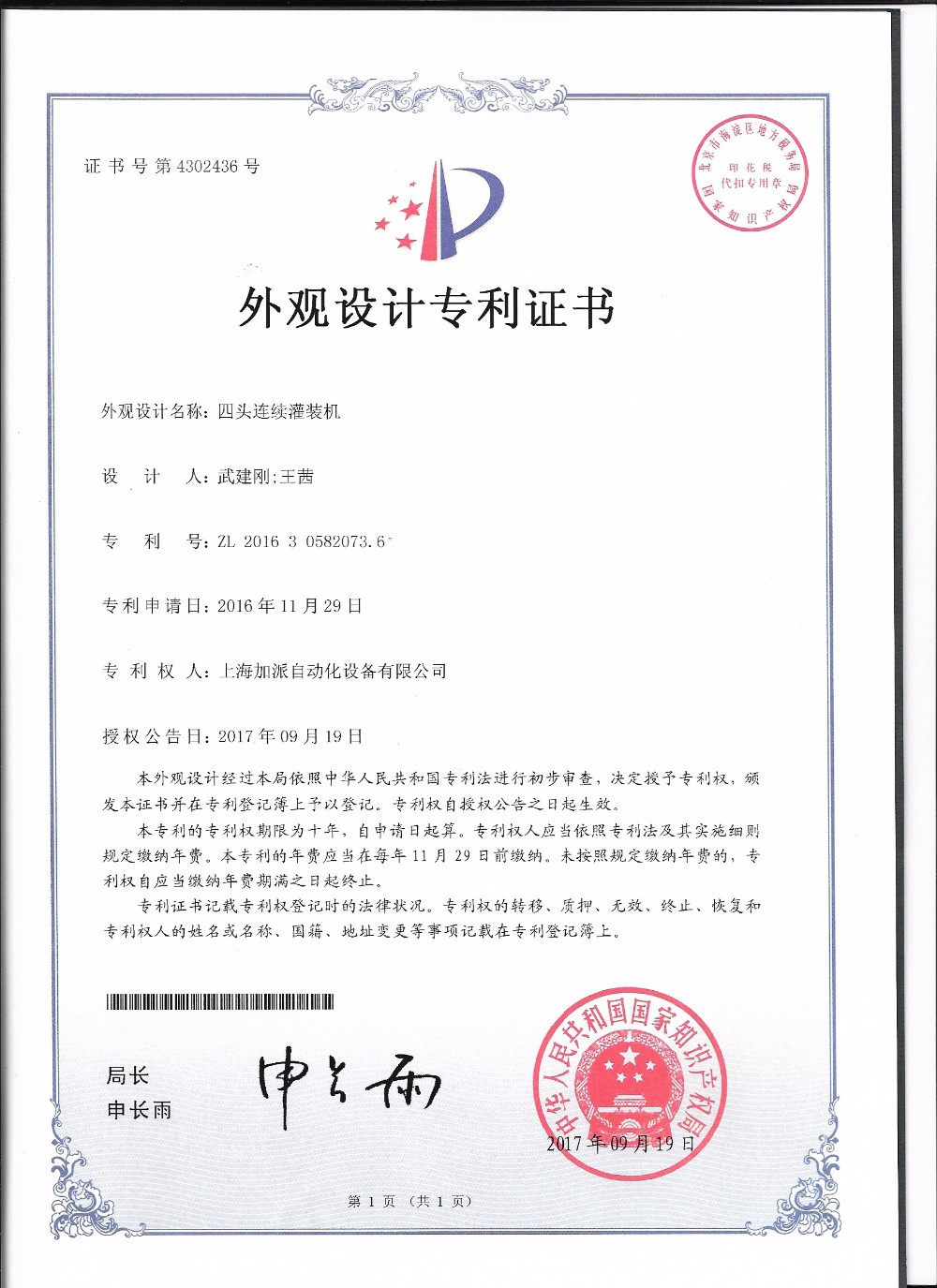

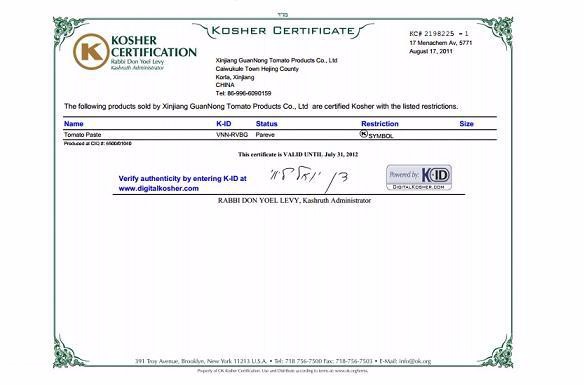

- Certification:

-

ISO

- Warranty:

-

One Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

Peach/cucumber canned production line

- Application:

-

Vegetables and fruits

- Color:

-

Silvery

- Feature:

-

Turn Key Project

- Item:

-

Automatic Canned Fruits Making Machine

- Capacity:

-

3-5t/h

- Material:

-

304 Stainless Steel

- Usage:

-

Industrial Usage

- Function:

-

Multifunctional

- Name:

-

Cucumber Canned Production Line

- Supply Ability:

- 10 Set/Sets per Year

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion. Fumigation-free package helps the smooth customs clearance. The big size machine will be fixed in container without package.

- Port

- shanghai

- Lead Time :

- 2-3months

The main process of canned food processing:

Raw material selection → Pre-treatment → Canning → Exhaust sealing → Sterilization and cooling → Insulation inspection → Package storage

The raw materials of fruits and vegetables :

Bamboo shoots, mushrooms, peppers, ketchup, cucumbers, radishes, green beans, apples, pears, citrus, peaches, cherries, pineapples, etc.

Packaging:

glass bottles, PET plastic bottles, cans, aseptic flexible packaging, roof bags, 2L-220L aseptic bags, carton packaging, plastic bags, 70-4500g tin cans.

Air Blowing & Washing Machine

1 Used to wash fresh tomato, strawberry, mango, etc.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc.

Filling machine

1.Adopt Italian technology, sub-head and double-headed, continuous filling, reduce return;

2.Using steam injection to sterilize, to ensure filling in aseptic state , the shelf life of product will twp years at room temperature ; In the filling process,

3.Using turntable lifting mode to avoid secondary pollution.

Retort

1. Quick opendoor structure, safety interlock.

2. With compressed air pipe so as to be convenience for counter-pressure processing by customers.

3.The bowl shell is with insulation layer, which could reduce the energy consumption.

4. Control system—- Touch screen +PLC it automatically fulfill the whole process of exhausting, heatingup, cooling of counter pressure and drainage.

Tube in tube sterilizer

1. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc.

2. Incorporated Italian technology and conform to Euro-standard

3. Great heat exchange area, low energy consumption and easy maintenance

4. Adopt mirror welding tech and keep the smooth pipe joint

5. Auto backtrack if not enough sterilization

6. CIP and auto SIP available together with aseptic filler

7. Liquid level and temp controlled on real time

A.Allotted for equipment inspection certificate and manual, to ensure that users properly install and use

B.Equipment to reach the destination, the company will send engineers to guide installation and commissioning and customer training until satisfied

C.The warranty period will be free to customers wearing accessories, shelf life outside of my company to provide parts at cost.

D. I provide lifelong maintenance service, including if necessary, to send engineers to the customer at the service.

1. What’s your payment terms?

T/T or L/C.

2. What’s your delivery time?

Usually we will arrange the shipment in 2-3months.

3. How about the packing?

Usually we provide the packing as carton. Of course, if you have special requirements on them, we will according to you.

4. What is loading port?

Usually is Shanghai.

5. What documents you provide?

Usually, we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.

6.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

7.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

8.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.

Welcome any inquiry! Tel/Wechat/Whatsapp:008613681836263

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most competitive prices. So Profi Tools offer you best value of money and we are ready to develop together with China Manufacturer for Banana Chips Fryer - Peach / Cucumber Canned Production Line – JUMP , The product will supply to all over the world, such as: Durban, Comoros, Malta, Looking forward, we will keep pace with the times, continuing to create new products. With our strong research team, advanced production facilities, scientific management and top services, we will supply high quality products to our customers worldwide. We sincerely invite you to be our business partners for mutual benefits.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.