1. smooth bucket structure against clamping fruits, suitable for tomato, strawberry, apple, pear, apricot, etc.

2. running stably with low noise, speed adjustable by transducer.

3. anticorrosive bearings, double sides seal.

CHINA Industrial fruit vegetable tomato / garlic / onion sauce / jam making plant

- Applicable Industries:

-

Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

Algeria

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

1 Year

- Core Components:

-

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

OEM

- Type:

-

PROCESSING LINE

- Voltage:

-

220V/380V

- Power:

-

3kw

- Weight:

-

80 TONS

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

ISO 9001,CE

- Warranty:

-

2 Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

tomato paste production line

- Material:

-

304 Stainless Steel

- Name:

-

tomato paste production line

- Application:

-

kinds of jams making

- Function:

-

Multifunctional

- Usage:

-

Industrial Usage

- Capacity:

-

3-5t/h

- Feature:

-

Easy Operation

- Item:

-

Automatic Fruits jams Machine

- 3 Set/Sets per Month onion paste making machine

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- Shnaghai

- Lead Time :

-

Quantity(Sets) 1 – 1 >1 Est. Time(days) 60 To be negotiated

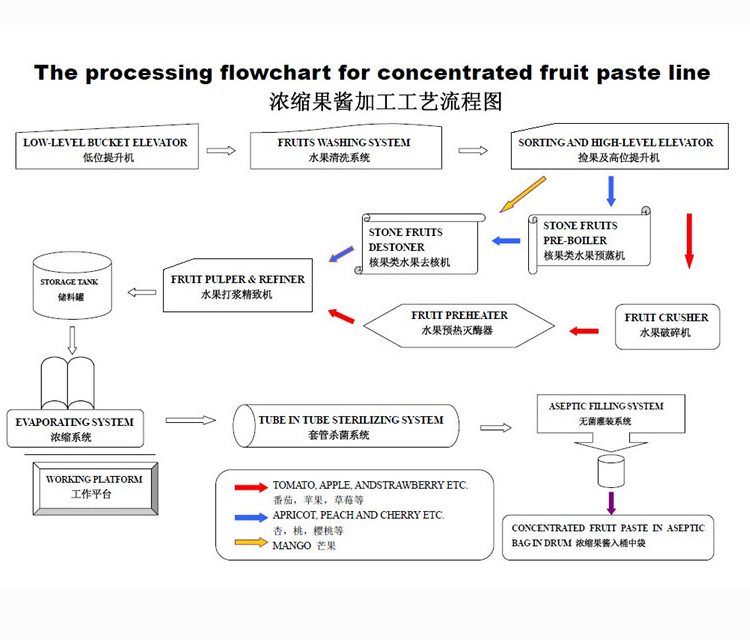

FRUIT JAM PROCESSING LINE

1. Packing: 5-220L aseptic drums, tin cans, plastic bags, glass bottles and so on

2.The whole line composition:

A: promotion system of the original fruits, cleaning system, sorting system, crushing system, pre-heating sterilization system, pulping system, vacuum concentration system, sterilization system, aseptic bag filling system

B: pump → blending drum → homogenization →deaerating → sterilization machine → washing machine → filling machine → capping machine → tunnel spray sterilizer → dryer → coding → boxing

2.The whole line composition:

A: promotion system of the original fruits, cleaning system, sorting system, crushing system, pre-heating sterilization system, pulping system, vacuum concentration system, sterilization system, aseptic bag filling system

B: pump → blending drum → homogenization →deaerating → sterilization machine → washing machine → filling machine → capping machine → tunnel spray sterilizer → dryer → coding → boxing

Bucket Elevator

Air Blowing & Washing Machine

1 Used to wash fresh tomato, strawberry, mango, etc.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc.

Peeling, pulping & Refining Monobloc (Pulper)

1. The unit can peel, pulp and refine fruits together.

2. The aperture of strainer screen can be adjustable (change) based on customer's requirement.

3. Incorporated Italian technology, high quality stainless steel material in contact with fruit material.

Belt press extractor

1. Widely used in extracting and dehydrating of many kinds of acinus, pip fruits, and vegetables.

2. the unit adopt advanced technology, big press and high efficiency, high degree of automatic, easy to operate and maintains.

3. the extraction rate can be get 75-85%(based on raw material)

4. low investment and high efficiency

Preheater

1. To inactivate enzyme and protect color of paste.

2. Auto temperature control and the out temperature are adjustable.

3. Multi-tubular structure with end cover

4. If the effect of preheat and extinguish enzyme failed or not enough, the product flow return to tube again automatically.

Evaporator

1. Adjustable and controllable direct contact heat treatment units.

2. Shortest possible residence time, presence of a thin film along the entire length of the tubes reduces holdup and residence time.

3. Special design of liquid distribution systems to ensure correct tube coverage. The feed enters at the top of the calandria where a distributor ensures film formation on the inside surface of each tube.

4. The vapor flow is co-current to the liquid and the vapor drag improves the heat transfer. The vapor and the remaining liquid are separated in a cyclone separator.

5. Efficient design of separators.

6. Multiple effect arrangement provides steam economy.

Tube in tube sterilizer

1. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc.

2. Incorporated Italian technology and conform to Euro-standard

3. Great heat exchange area, low energy consumption and easy maintenance

4. Adopt mirror welding tech and keep the smooth pipe joint

5. Auto backtrack if not enough sterilization

6. CIP and auto SIP available together with aseptic filler

7. Liquid level and temp controlled on real time

|

Our Main Business Products

|

||

|

1

|

Tomato paste / puree / jam / concentrate, ketchup, chilli sauce , other fruit & vegetables sauce / jam processing line

|

|

|

2

|

Fruit & vegetables ( orange , guava, cirtrus, grape, pinapple, cherry, mango, apricot.etc. ) juice and pulp processing line

|

|

|

3

|

Pure, mineral water, Mixed beverage, drink (soda, Cola, Sprite, carbonated beverage, no gas fruit drink, herbal blend drink, beer,cider, fruit wine .etc. ) production line

|

|

|

4

|

Canned fruit & vegetables ( tomato, cherry, beans, mushuroom, yellow peach, olives, cucumber, pineapple, mango, chili, pickles and so on. ) production line

|

|

|

5

|

Dried fruit & vegetables ( dried mango, apricot, pineapple, raisin, blueberry .etc. ) production line

|

|

|

6

|

Dairy (UHT milk, pasteurized milk, cheese, butter, yogurt, milk powder, margarine, ice cream)production line

|

|

|

7

|

Fruit and vegetable powder (Tomato, pumpkin, cassava powder, strawberry powder, blueberry powder, bean powder, etc. ) production line

|

|

|

8

|

Leisure snack (Dried freeze-dried fruit, puffed food, french fried potato chips, etc. ) production line

|

|

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1.What is the warranty period of the machine?

One year. Except the wearing parts, we will provide free maintenance service for the damaged parts caused by normal operation within warranty. This warranty does not cover wear and tear due to abuse, misuse, accident or unauthorized alteration or repairs. Replacement will be shipped to you after photo or other evidence are provided.

2.What service can you provide before sales?

Firstly, we can supply the most suitable machine according to your capacity. Secondly, After getting your workshop dimension, we can design the workshop machine layout for you. Thirdly, we can provide technical support both before and after sales.

3.How can you guarantee the after sales service?

We can send engineers to guide the installation, commissioning, and training according to the service agreement we signed.