CE standard stainless steel pomegranate juice production line with factory price

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMPFRUITS

- Model Number:

-

JPF-SL5024

- Type:

-

complete plan for a tomato product engineering project

- Voltage:

-

220V/380V

- Power:

-

2.2kw

- Weight:

-

150kg

- Dimension(L*W*H):

-

900*460*740mm

- Certification:

-

CE/ISO9001

- Warranty:

-

1 Year warranty,life-long aftersell service

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

pomegranate production machinery

- Application:

-

building pomegranate processing

- Name:

-

SH-JUMP turnkey tomato processing project

- Feature:

-

turnkey solution,from A to Z service

- Capacity:

-

reasonable design for customer,100kg/H to 100T/H

- Material:

-

SUS304 Stainless Steel

- Scale:

-

home scale and commercial scale

- Function:

-

Multifunctional

- Usage:

-

Industrial Usage

- Color:

-

Customers' Requirements

- 20 Set/Sets per Month

- Packaging Details

- Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion.Fumigation-free package helps the smooth customs clearance.The big size machine will be fixed in container without package.

- Port

- shanghai port

- Lead Time :

- 2-3 months

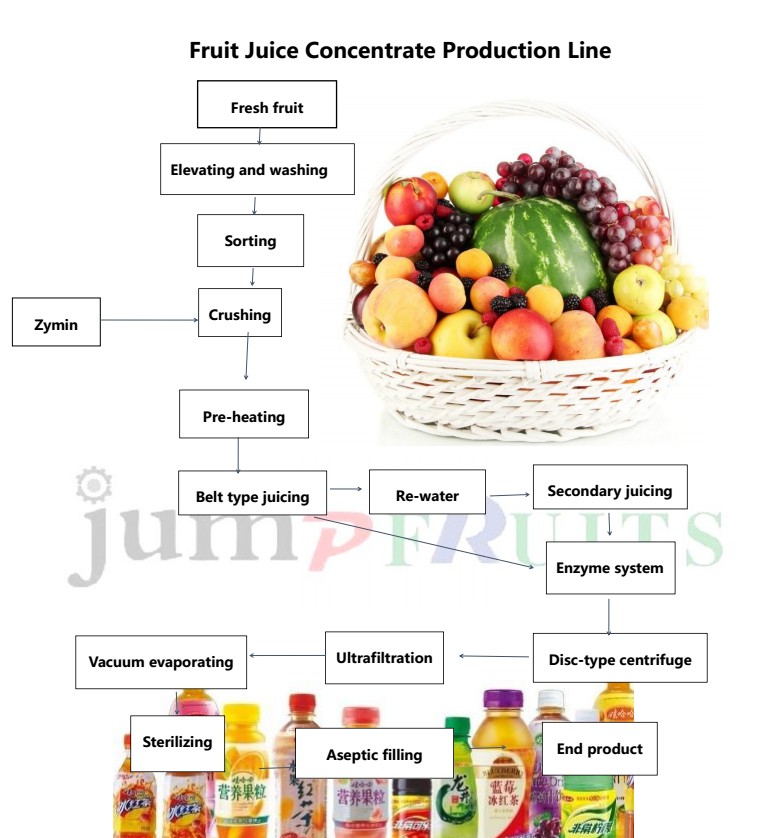

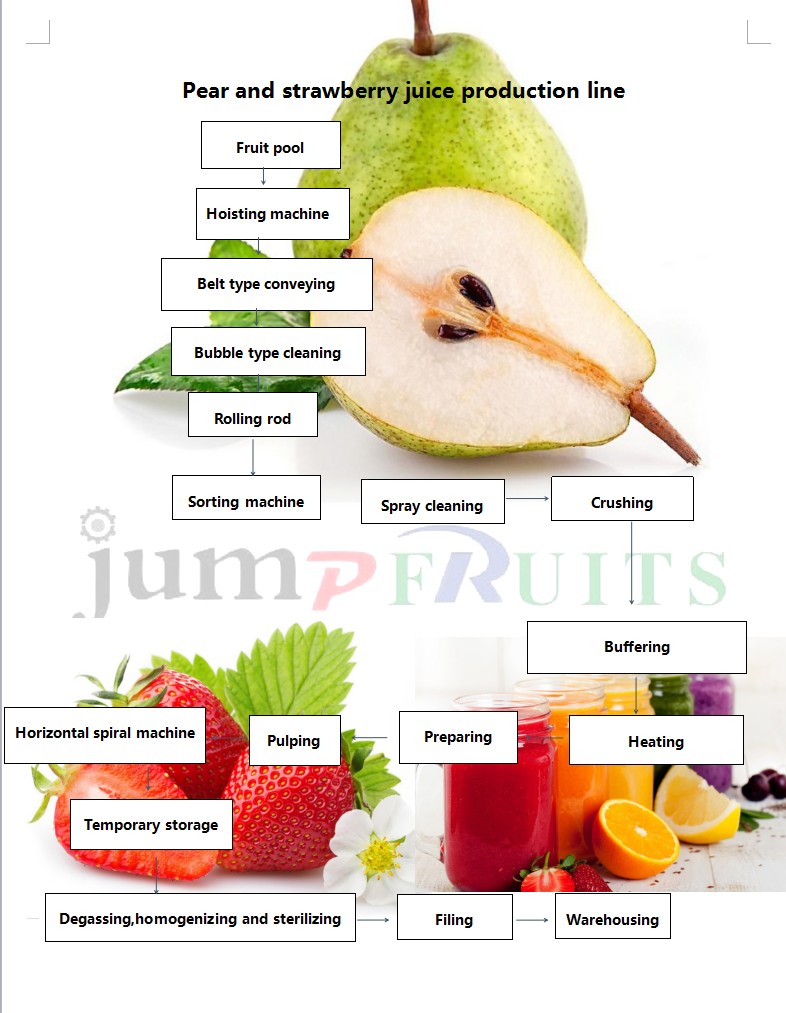

PROCESSING FLOW FOR REFERENCE:

pomegranate production line

Cleaning – selecting – crushing – preheating – beating – filtering – concentrating – deploying – sterilizing – aseptic filling – finished packing etc.

*Capacity: 60t/day, 90t/day,150t/day,240t/day, 300t/day,500t/day, 600t/day, 800t/day, 1000t/day,1500t/day.

*End products brix: 28-30%,30-32%,36-38%

*Application: This production line includes multi-function crushing machine and juicing machine,which can produce apple juice,pear juice ,carrot juice, guava juice and many other fruit juice.

*Control System:This

production line can adopt manual and automatic control when under 300 tons.

Characteristics:

1.freely placed

2.Convenient maintenance

3.steady performance

4.easy operate

To design pomegranate processing line of energy and capital intensive. Just free free to contact us.

Pomegranate production machinery

* Production output from 1000-35000 bottles per hour.

* Packaging forms include cans, PET bottles, glass bottles, roof bags, sterile soft packs

* Flexible production line configuration, according to customer needs of different end products, you can configure different functions of the device

* Available basket-type, continuous counter-current and other means of extraction

* The entire line of modular design, a combination of different processing technology

* High degree of automation, saving labor

* With cleaning system, easy to clean

* System materials contact part of all 304 stainless steel, in full compliance with food hygiene and safety requirements

Package: glass bottle, PET plastic bottle, cans, aseptic soft package, roof pack 2L-220L sterile bag, carton package, plastic bag, 70-4500g tin can.

Whatsapp/Line/Wechat/Mobile: 008618018622127 Welcome any inquiry!

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of "Quality and Service Branding", after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

Whatsapp/Line/Wechat/Mobile: 008618018622127 Welcome any inquiry!

Pomegranate processing line

Our Advantages:

1.Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop services, from your warehouse designing(water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

2.15 years export experience, easily transport cargo to your door

3.customized service, we will try our best to meet your requirement.

4.Quality guarantee: 12 months. After that, engineers also available on your traval expense and spare parts cost.We offer life-long after-sale service.

Main advantages of our system line:

1. High production speed achieved by a newly designed head system (single head or twin heads available), improved reliability from a fully PLC controlled self diagnostic operational mode.

2. Greater versatility by meeting various packing standards with different products.

3 Coordinates well with the tube in tube sterilizer, if some malfunction with the filler, the product will be automatic flow back into the buffer tank before the UHT sterilizer.

4. The use of a hermetically sealed empty bag ensures the bag will remain sterile before it is filled.

5. High pressure saturated steam is used for sterilization of the fitment, cap and exposed portion of the filler prior to each filling cycle. NO CHEMICALS are required.

6. The sealing of the fill valve on the interior of the fitment keeps product completely away from the package sealing area.

7. The hermetic heat sealing of the fitment provides a tamper evident closure and a superior oxygen barrier.

8. The overall aseptic design of the filler allows uninterrupted. Operation throughout a complete tomato/fruit season, maximizing your plant’s efficiency

9. CIP and SIP available together with tube in tube sterilizer

We can suggest customer the most suitable machine according to their formula and Raw material. “Design and development”, “manufacturing”, “installation and commissioning”, “technical training” and “after sales service”. We can introduce you supplier of raw material, bottles, labels etc. Welcome you to our production workshop to learn how our engineer produce. We could customize machines according to your real need, and we could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

After-sale service

1.Installation and commissioning: We will send experienced engineering and technical personnel to be responsible for the installation and commissioning of the equipment until the equipment is qualified to ensure that the equipment is in time and put into production;

2.Regular visits:To ensure the long-term stable operation of the equipment, we will be based on customer needs, provide one to three times a year to come to technical support and other integrated services;

3.Detailed inspection report: Whether the inspection regular service, or the annual maintenance, our engineers will provide a detailed inspection report for the customer and the company reference archive, in order to learn the equipment operation at any time;

4.Fully complete parts inventory: In order to reduce the cost of parts in your inventory, provide better and faster service, we prepared a complete inventory of parts of equipment, to meet customers possible period of want or need;

5.Professional and technical training:In order to ensure the performance of the customer’s technical personnel to become familiar with the equipment, correctly grasp the equipment operation and maintenance procedures, in addition to install on-site technical training. Besides, you also can hold all kinds of professionals to the factory workshops, to help you faster and more comprehensive grasp of technology;

6.Software and consulting services:In order to allow your technical staff to have a greater understanding of the equipment related counseling, I will arrange to send the equipment regularly sent to the advisory and latest information magazine.No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

Products categories

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu