Best Price Concentrate Tomato Paste Evaporator

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

JUMP

- Model Number:

-

JPML-1127

- Type:

-

processing line

- Voltage:

-

220V/380V

- Power:

-

2.2kw

- Weight:

-

2t

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

CE ISO

- Warranty:

-

1 Years

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

tomato paste evaporator

- Production capacity:

-

500kg-100T/H

- Material:

-

SUS304

- Function:

-

whole processing line

- Usage:

-

Dairy product production line

- After-sales Service:

-

overseas engineer service available

- Advantage:

-

life-long after-sales Service

- Name:

-

pasteurization machine

- Application:

-

Root Vegetables

- Capacity:

-

3-5t/h

- Supply Ability:

- 10 Set/Sets per Month tomato paste evaporator

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- shanghai port

- Lead Time :

- 50 days

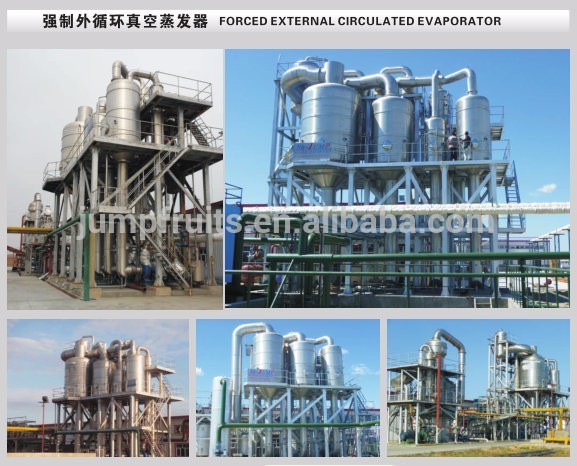

Forced circulating single-effect, double-effect, triple-effect and multi-effect evaporators are applicable for low temper-ature concentration of high concentration and high viscosity materials containing indissoluble soiid things in food, med-icine, chemical industry, biological project,environment pr-otection project and waste liquid recovery etc, industries.

MAIN CHARACTERISTICS

1. The whole set system has reasonable and beautiful design stable operation, high efficiency, energy sav-ing and low steam consumption.

2. Large concentration ratio, forced circulating type, whi-ch can make the materials of larger viscosity easily flow and evaporate and shortens the concentrating time. 3. The special design can make modifications of effects easily to realize production of various products.

4. Low evaporation temperature. The heat quantity can be fully used.The heating of materials is warm, so it is applicable for concentration of heat sensitive materials.

5. After forced circulating, the evaporator is heated ev-enly in the pipe with high heat transfer coefficient, in order to prevent the occurrence of’dry walls”.

6. The materials and liquids are separated after coming into the separator.The effect of separating is greatly improved, and it is flexible to operate.

7. The who e set equipment is quite compact, and oc-cupies little area,and the ayout is simple and fluent, all of which are the developing er dency of large-sized whole set evaporating equipments.

8. Con nuous materials inlet and outlet, and the liquid level of materials and needed concentration can be automatically controlled.

Main Features

we take advantages of the comprehensive and technical cooperation with the Italian company partner, now in fruit processing, cold breaking processing, multi effect energy saving concentrated, sleeve type sterilization and aseptic big bag canning has made domestic and unmatched technical superiority. We can provide the entire production line processing 500KG-1500 tons of raw fruit daily according to the customers.

Turnkey solution. No need worry if you know little about how to carry out the plant in your country.We not only offer the equipment to you,but also provide one-stop service, from your warehouse designing (water, electricity ,staff) , worker training, machine installation and debugging, life-long after-sale service etc.

Our company adheres to the purpose of “Quality and Service Branding”, after many years of efforts, has set a good image in the domestic ,due to superior price, and excellent service , at the same time, the company products are also widely infiltrated into Southeast Asia, Middle East, Africa, South America, Europe and many other overseas markets.

Whatsapp/Wechat/Mobile: 008613681836263 Welcome any inquiry!

UHT milk sterilizer machine

1 Capacity of plant: 2T-300T/D

2 Products type: 1 or 2 or more kinds.

homogenizer

Applied to the refinement or emulsification of juice, jam, beverage.

With frequency conversion control and centralized control cabinet

Rated handling capacity 1T/H

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Power:7.5KW

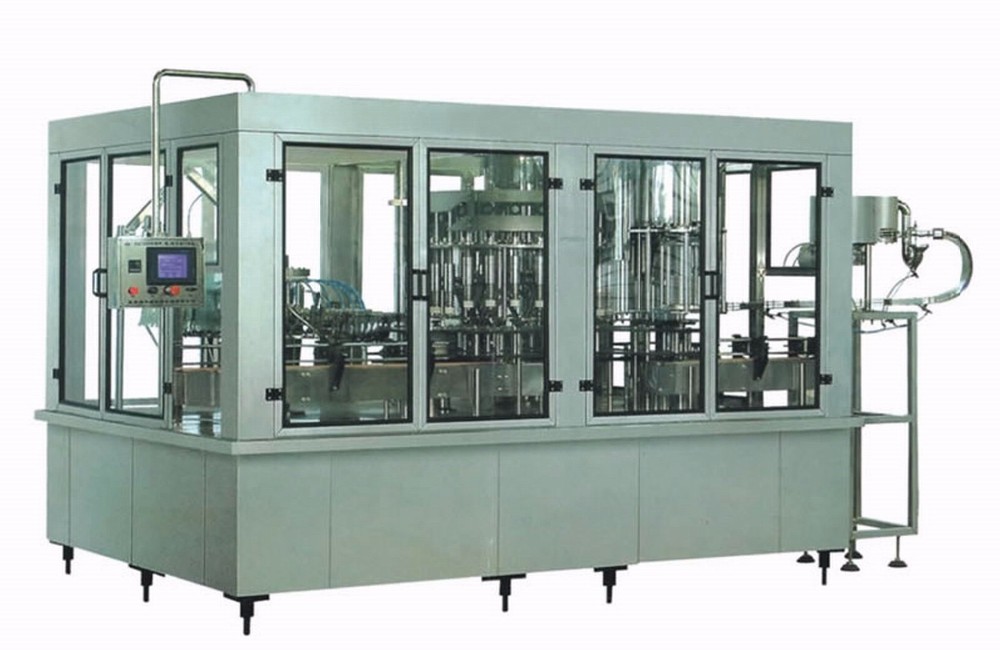

Filling maching

Specially suitable for tomato paste, mango puree and other viscous product.

35-50 bottle per min

Filling sachet valume:10-500g

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory,pickup service.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Own tomato planting base in Xinjiang+Machinery processing line+15 years export experience+professional customerize service=your reliable business partner

1.Planting base in Xinjiang,producing tomato products(paste/powder,etc) in world top quality,with production capability of over 1000T/day

2.Factory of machinery and engineering vegetables and fruit paste processing,juice drink processing and fruit powder process etc.,absorbing world advanced technology.

3.15 years export experience, easily transport cargo to your door

4.customerized service, revise our products or OEM for your requirement