Automatic Turn key project UHT Milk Processing Line with Sterilizer

- Applicable Industries:

-

Manufacturing Plant, Food & Beverage Factory, Farms, Food & Beverage Shops

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

Algeria, Uzbekistan

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

Hot Product 2019

- Warranty of core components:

-

1 Year

- Core Components:

-

Engine

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

OEM

- Type:

-

Turn key project

- Voltage:

-

220V/380V

- Power:

-

3kw

- Weight:

-

50 TONS

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

ISO 9001,CE

- Year:

-

2019

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Field installation, commissioning and training, Engineers available to service machinery overseas

- Product name:

-

UHT Milk Processing Line

- Item:

-

small milk processing line

- Material:

-

304 Stainless Steel

- Capacity:

-

0.5-5t/h

- Feature:

-

Turn Key

- Color:

-

Customers' Requirements

- Usage:

-

Industrial Usage

- Function:

-

Multifunctional

- 3 Set/Sets per Month

- Packaging Details

- carton box

- Port

- shanghai

- Lead Time :

-

Quantity(Sets) 1 – 1 >1 Est. Time(days) 40 To be negotiated

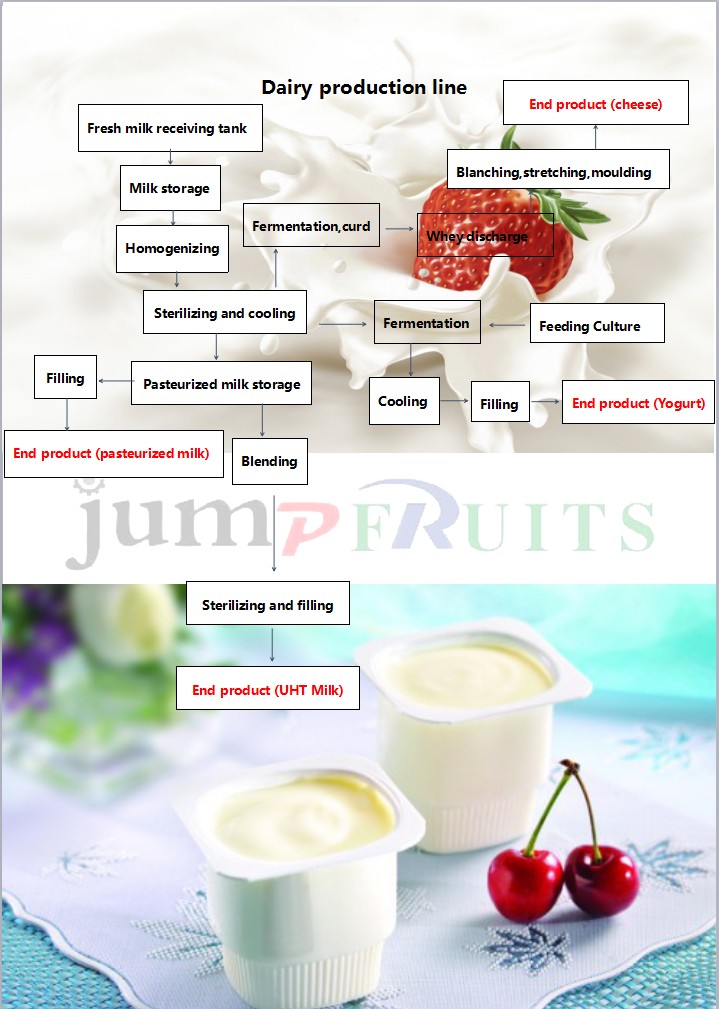

Product Application

Milk production line mainly produces a variety of flavors of sterilized milk, pasteurized milk and reconstituted milk, peanut milk, milk and so on, a full set of fresh milk production line mainly include: breast milk collection system, mixing system, net and standardization system, homogeneous degassing system and sterilization system, filling system, etc.

Milk a full set of equipment:

Storage tanks – - – the milk tank – hot and cold beverage pump cylinder cream separator – to take off the angry machine – mixing cylinder – homogenizer – ultra high temperature sterilization machine – plate heat exchanger – seed tank fermentation tank – sterilization machine, automatic filling machine.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Machine Parts

Name: Spray drying

Brand: Jump

Original: China

This equipment is used to dry solid liquid such as solution and suspending liquid. In the tower, the materials can be heated in short time and evaporated quickly and the temperature of heat exchanger is lower so that it has little impact on the solubility, color, flavor and nutrition of the

product. Therefore, this equipment is widely used in the industries of food, medicine and

chemical products, especially suitable to dry the heat-sensitive materials by spraying such as

thick milk, soy milk, egg liquid, blood meal, medicament, yeast and food additives.

Main Features

Name: Bliwing Cylinder

Brand: FESTO

Original: Germany

Special suitable for fruit/vegetable paste and juice or juice concentrate,dairy product and other high viscous or fluent product.

Applicable to aluminum foil compound aseptic bag from 5L-220L or 1000L by means of easy adjustment with simple change parts.Easily adjustable with simple change parts according to

The unite is consisted of: aseptic filling head, accurate electronic balance, drum conveying roller, PLC Control system, control cabinet, steam barrier and protection system, operation platform, etc.Main structure with SUS304 stainless steel, combined Italy technology and based on

Europe standard.

Provide several security measures(position controlling, computation controlling, temperature controlling) to prevent the machine from destroying and guarantee the product’s quality Products’ valves, filler head and other moving parts have steam barrier for protection

Keep the filling chamber sterilized all the time using steam protection

When shifting the aseptic bag or some thing wrong with the filler, the product will be auto backtracked into the buffer tank before the tube in tube sterilizer.

Full aUto CIP(clean in place) and SIP(sterilize in place) available simultaneously together with tube in tube sterilizer

Automatically print the black and white label and other data the customer specified such as the filling date, filling time, filling weight, product code or others, if you required.

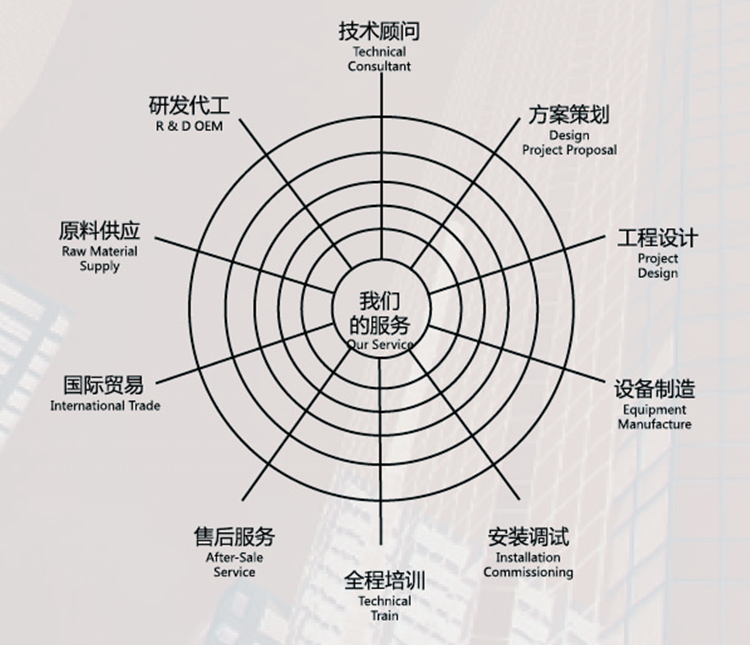

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Products categories

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu