Automatic small tomato sauce processing line plant for sale

- Applicable Industries:

-

Food & Beverage Factory

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

Jumpfruits

- Model Number:

-

JUMP-FQJL

- Type:

-

PROCESSING LINE

- Voltage:

-

220V/380V

- Power:

-

3kw

- Weight:

-

5 TONS

- Dimension(L*W*H):

-

1380*1200*2000mm

- Certification:

-

ISO 9001,CE

- Year:

-

2019

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Field installation, commissioning and training

- Product name:

-

tomato sauce processing plant

- Material:

-

304 Stainless Steel

- Application:

-

Kinds

- Function:

-

Multifunctional

- Usage:

-

Industrial Usage

- Capacity:

-

500-1000kg/h

- Keywords:

-

Small Fruit puree processing Machine

- Final product:

-

Tomato Sauce

- 3 Set/Sets per Month tomato sauce processing line plant

- Packaging Details

- 40GP

- Port

- shanghai

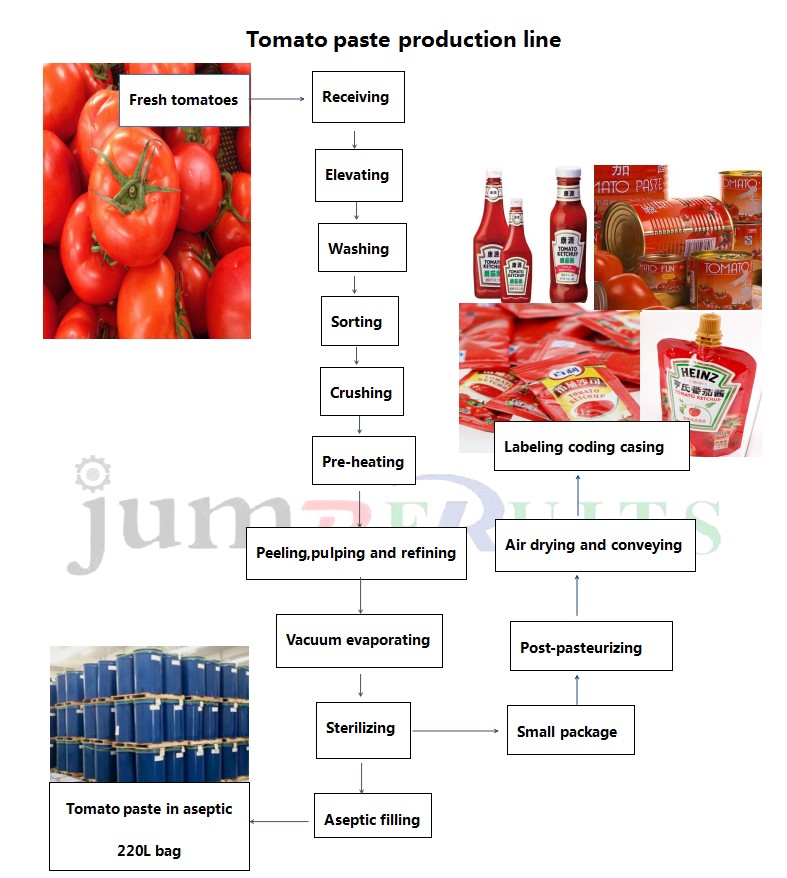

- Picture Example:

-

- Lead Time :

-

Quantity(Sets) 1 – 1 >1 Est. Time(days) 90 To be negotiated

A: promotion system of the original fruits, cleaning system, sorting system, crushing system, pre-heating sterilization system, pulping system, vacuum concentration system, sterilization system, aseptic bag filling system

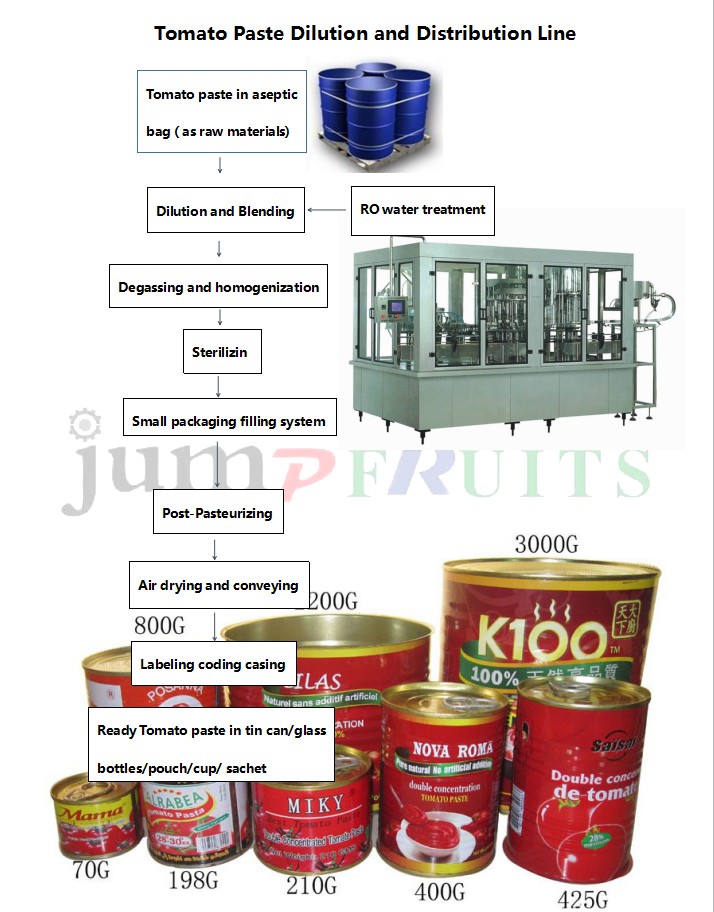

B: pump → blending drum → homogenization →deaerating → sterilization machine → washing machine → filling machine → capping machine → tunnel spray sterilizer → dryer → coding → boxing

2. The final product concentration: Brix 28-30%, 30-32% cold broken and heat broken, 36-38%

Shanghai Jump Automatic Equipments Co., Ltd.

1.Professional engaged in whole plant equipment design, manufacturing, R & D and turnkey project for Fruit&vegetable deep processing ,Beverage Processing and Dairy Processing.

2.Over forty years’ rich experience and sound technical strength.

3.More than 110 established fruit and vegetable processing production lines.

4.Has established stable technical cooperation with the Italy FBR, Ing. Rossi, Bertuzzi CFT.

5.We can provide the entire production line processing 20-1500 tons of raw fruit daily according to the customers

6.Products are also widely infiltrated into overseas markets.

7.With15 years export experience, easily transport cargo to your door

8.Customerized service, revise our products or OEM for your requirements

Fresh tomato washing / cleaning machine line

Tomatoes are washed by high pressure water in the fruit washing machine. Scraper elevator conveys the cleaned tomatoes to the next procedure.

Fruit roller sorting machine

Cleaned fruits enter into the machine from the feeding hopper, and rotate forward toward the outlet. Workers pick out the unqualified tomatoes to ensure the quality of the end product.

Tomato fruits crusher

Used for conveying and crushing of tomatos, preparing for pre-heating and pulping.

Tomato paste Tubular Preheater

Tubular preheater increases the temperature of the pulp by steam heating, so that to soften the pulp and deactivate the enzymes.

Tomato / mango Pulping Machine

Single-channel pulping machine is used for automatic separation of pulp and residue from the crushed and preheated tomatoes. The material from the last procedure enters into the machine through the feed inlet, and spirals toward the outlet along the cylinder. By centrifugal force, the material is pulped. The pulp passes through the sieve and is sent to the next procedure, while the skin and seeds are discharged through the residue outlet, achieving the aim of automatic separation. The pulping speed can be changed by changing the sieve and adjusting the lead angle of the scraper.

Tomato paste double effect vacuum evaporator

This equipment is used for vacuum concentration of tomato pulp under low temperature. Steam is fed into the jacket at the lower part of the boiler, making the material under vacuum boil and evaporate. Blender in the boiler helps strengthen the flowing of the material.

Tubular Sterilizer for tomato paste

Tubular sterilizer increases the temperature of the concentrate by steam heating, achieving the aim of sterilization.

CIP clean system

Semi-automatic cleaning system

Including acid tank ,base tank ,hot water tank, heat exchange system and controlsystems. Cleaning all the line.

Tomato paste filling sealing and packaging machine

Specially suitable for tomato paste, mango puree and other viscous product.

Products categories

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu