Automatic Hot Chili Sauce Filling Machine In Glass Plastic Bottles

- Condition:

-

New

- Place of Origin:

-

Shanghai, China

- Brand Name:

-

OEM

- Model Number:

-

JP-LJM0025

- Type:

-

hot sauce making machine

- Voltage:

-

220V/380V

- Power:

-

3kw

- Weight:

-

40 TONS

- Dimension(L*W*H):

-

2100*1460*1590mm

- Certification:

-

CE/ISO9001

- Warranty:

-

One Year

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

hot sauce making machine

- Material:

-

304 Stainless Steel

- Application:

-

Kinds

- Function:

-

Multifunctional

- Capacity:

-

3-1500T/D

- Usage:

-

Industrial Usage

- Feature:

-

Turn Key Project

- Color:

-

Customers’ Requirements

- Name:

-

chili sauce making machine

- Item:

-

automatic hot sauce filling machine

- Supply Ability:

- 3 Set/Sets per Month automatic hot sauce filling machine

- Packaging Details

- 1.Stable wooden package protects machine from strike and damage. 2.Wound plastic film keeps machine out of damp and corrosion.3.Fumigation-free package helps the smooth customs clearance.4.The big size machine will be fixed in container without package.

- Port

- shanghai

- Lead Time :

- 60 days after receiving 30% payment

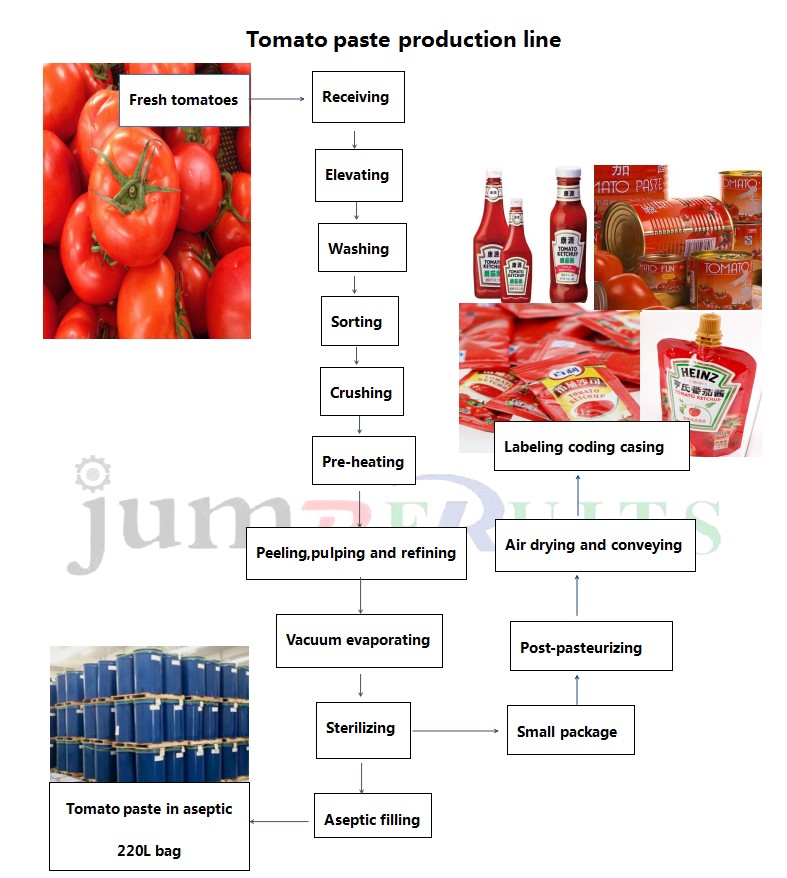

Hot chili sauce making machine

Package: glass bottle, PET plastic bottle, cans, aseptic soft package, roof pack 2L-220L sterile bag, carton package, plastic bag, 70-4500g tin can.

Tomato paste & hot chili sauce processing line

Tomato washing machine.

This machine is mainly used for washing of many kinds of fruits and vegetables. We can make the suitable washing machines according to custom ers’r equirements.

Specification

1). Machine types : air-blowing washing machine, spray washing machine, brushing washing machine etc.

2). Processing Capacity : 3-30tons/hour.

3). Material : SUS 304 stainless steel.

4). The capacity and m ater ial can be adjusted according to the custom ers’requirements.

Tomato pulping machine

This machine can be used to pulp on the following fruits

1.Stone fruits after the stone has been removed, such as mango, peach, apricot, date

2.Also used for the baccas (Chinese goose beery and strawberry)

3.Kernel fruits after been cooked and softened (such as apple.

pear. pumpkin)

Tomato paste evaporator

SYSTEM COMPONENTS

Composed of evaporators of various effects, separators of various effects, condenser, circulating pump, pump between effects, vacuum and drainage system, branch cylinder, operation platform, electric meter control cabinet, value, pipe etc.

Tomato paste sterilizing machine

Techncal:

Water Bath Squeegee Sterilization Machine is made of SUS304-2B stainless steel,which is composed of transfer squeegee,machine body ,piping system,electricity controller cabinet.Products can be transferred into pointed position by roller chain.The sterilization time can be regulated by changing the transducer rotating speed .This machine is used on the sterilization of packed jelly or PE/PP BOTTLES.

Tomato paste aseptic filling and packaging machine

1. Special suitable for fruit/vegetable paste and juice or juice concentrate, dairy product and other high ciscous or fluent product.

2. Applicable to aluminum foil compound aseptic bag from 5L-220L or 1000L by means of easy adjustment with simple change parts. Easily adjustable with simple change prats according to the aseptic bag volume and size.

3.The unite is consisted of aseptic filling head, accurate electronic balance, drum conveying roller, PLC Control system, control cabinet, steam barrier and protection system, operation platform, etc.

4.Main structure with SUS304 stainless steel, combined Italy technology and based on Europe standard.

5.Provide several security measures(position controlling, computation controlling, temperature contorlling) to prevent the machine from destroying and guarantee the product’s quality. Products’valves, filler head and other moving parts have steam barrier for protection, Keep the filling chamber sterilized all the time using steam protection. when shifting the tube in tube sterilizer. Full auto cIp(clean in place) and SIP(sterilize in place) available simultaneously together with tube sterilizer. Automatically print the black and white label and other data the customer soecified sucH as the filling date, filling weight, product code or others, if you required.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.